VIDEO: htttp://www.youtube.com/v/i5S9uD6YLD0

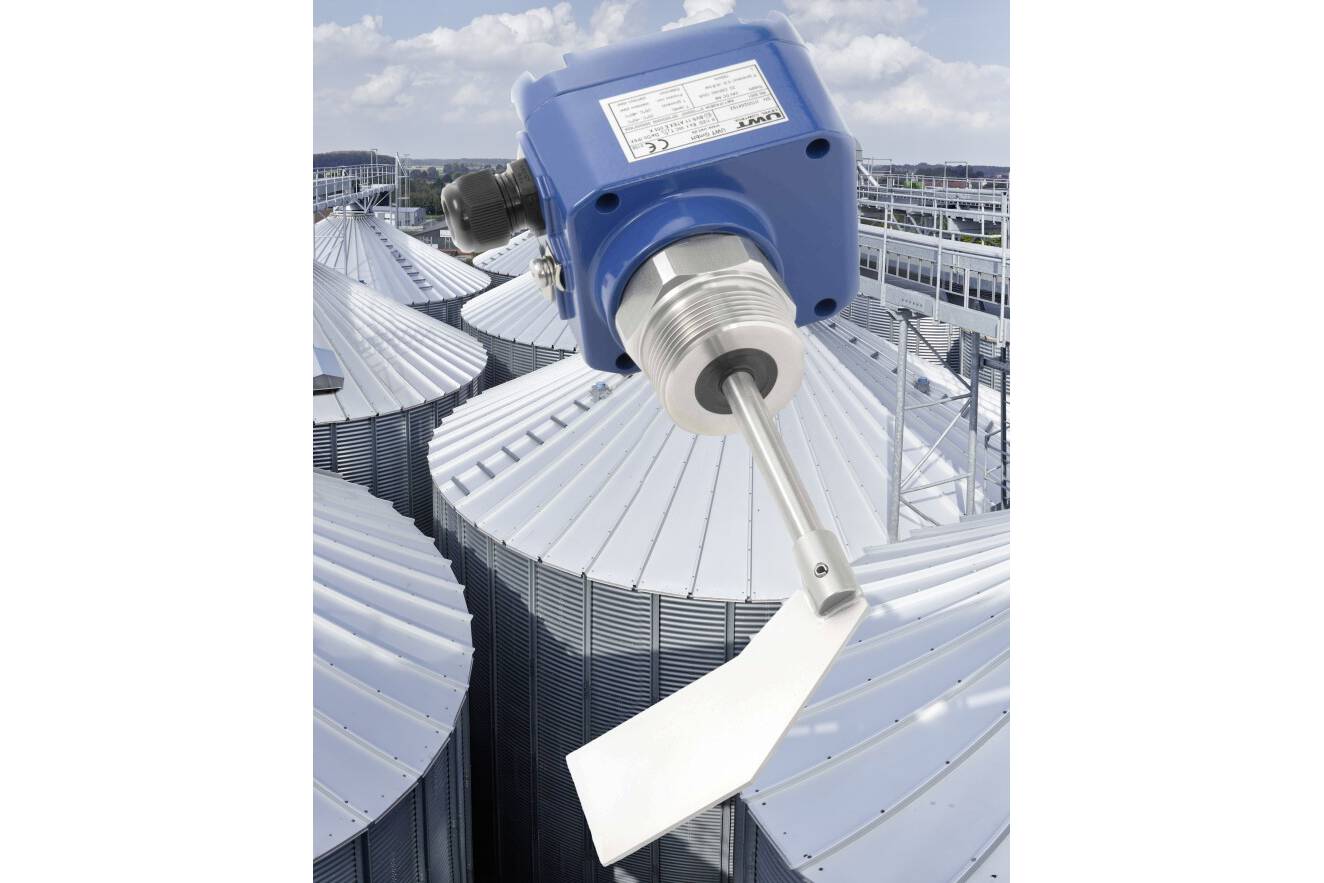

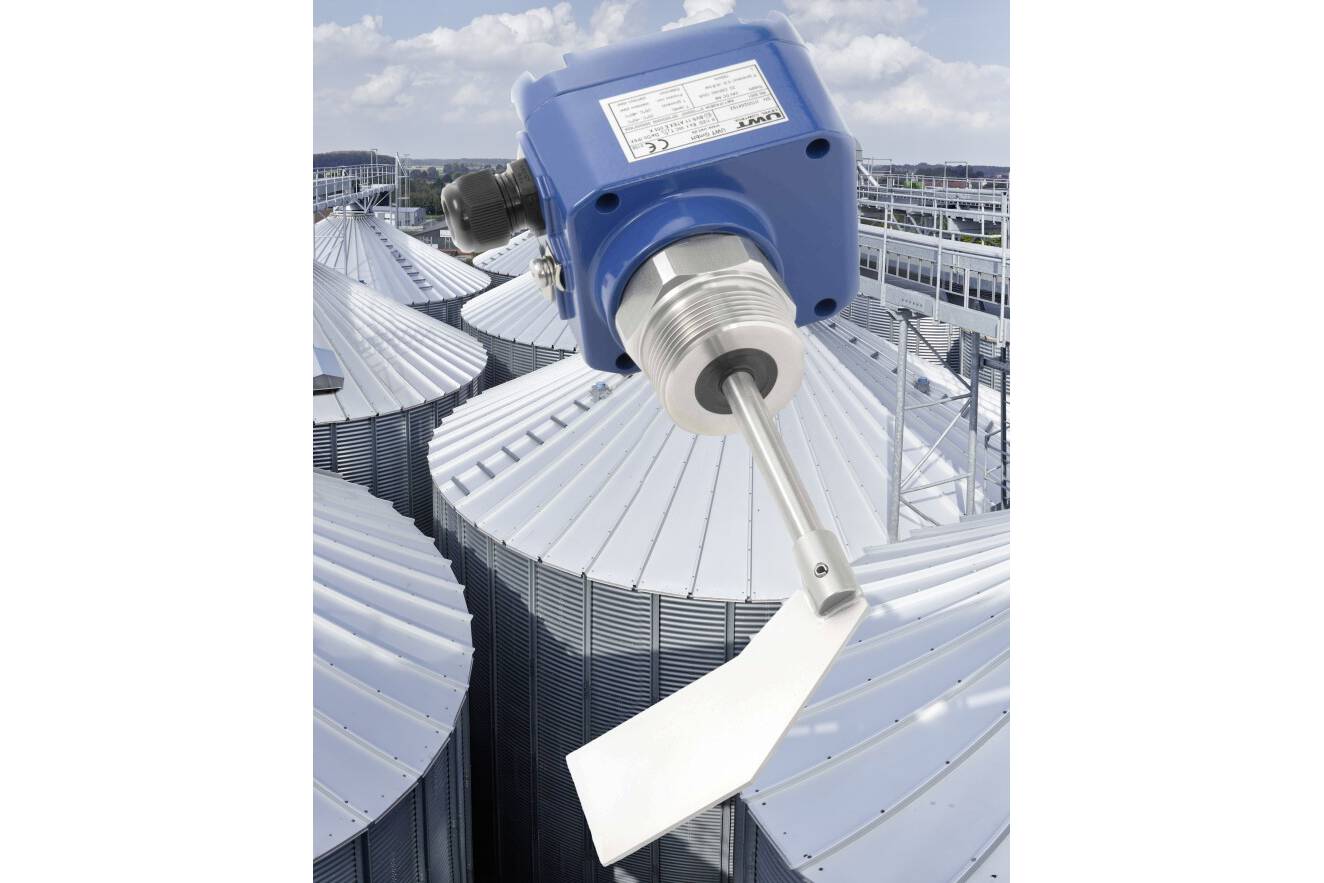

Rotary paddle Rotonivo® the reliable solution for level control

Simple and reliable measurement technology by UWT

A level limit sensor has to cope with low bulk density, bridging, caking, abrasiveness, corrosion, leverage forces, high and low process temperatures, electrostatic charging and so on. Rotating level limit switches of UWT have been designed to meet these challenges of different industry sectors and cover various changing approaches, also within extraordinary applications. The rotating paddle switch can be used as full, demand or empty detectors in silos or containers.

The trusted, multifunctional and maintenance free unit for level monitoring of bulk goods is versatile and has a modular design. With its simple electromechanical measuring principle it can also be adapted for extreme process conditions. A motor driven shaft causes the vane to rotate. Once the material level reaches the vane, thereby preventing further rotation, this creates a torque, which is converted via a switch to an electric signal. When the vane is free again of the material, the output signal is reset and the motor driven shaft rotates again.

The Rotonivo® provides very precise level limit detection as the sensor is unaffected by dust as well as the build-up of adhesion. The Rotonivo® 3000 models as high temperature version handle process temperatures up to +1100°C. Depending on the given conditions the units are equipped with the necessary sealing (Viton, Teflon, Ceramics). The simple and reliable measuring device is easy and fast installed and needs no further maintenance.

The PNP electronics for the Rotonivo® RN 3000 and RN 4000 ranges uses 3-wire electronics technology with a non-contact output, open collector, PNP. These electronics can be connected to any standard PLC with 24V DC power supply and PNP input card.

Further the sensor has a mechanically stable shaft bearing design with ball-bearing and a robust aluminum die-cast housing.

With the whole Rotonivo® portfolio being internationally certified with amongst others ATEX, FM and new Inmetro and TR-Cu-Ex it is conform to regulations for use in hazardous areas all around the world. The Rotonivo® 6000 series is also certified to SIL 2 (safety integrity level 2), particular for systems with hazard-causing processes, such as in chemical plants where the consideration of functional safety has become indispensable.