Dust, high temperatures or agitated surfaces – challenging measuring conditions are part of everyday operations in many industries. Continuous level measurement using non-contact radar has proven to be one of the most reliable and versatile methods for a wide range of applications. This also includes sensitive areas with particularly high hygiene requirements.

With UWT’s radar technology, levels can be measured precisely and without contact – even under the toughest conditions. Precise Level Measurement with Radar – Reliable, Non-contact, Future-Proof

Two main technologies radar sensors

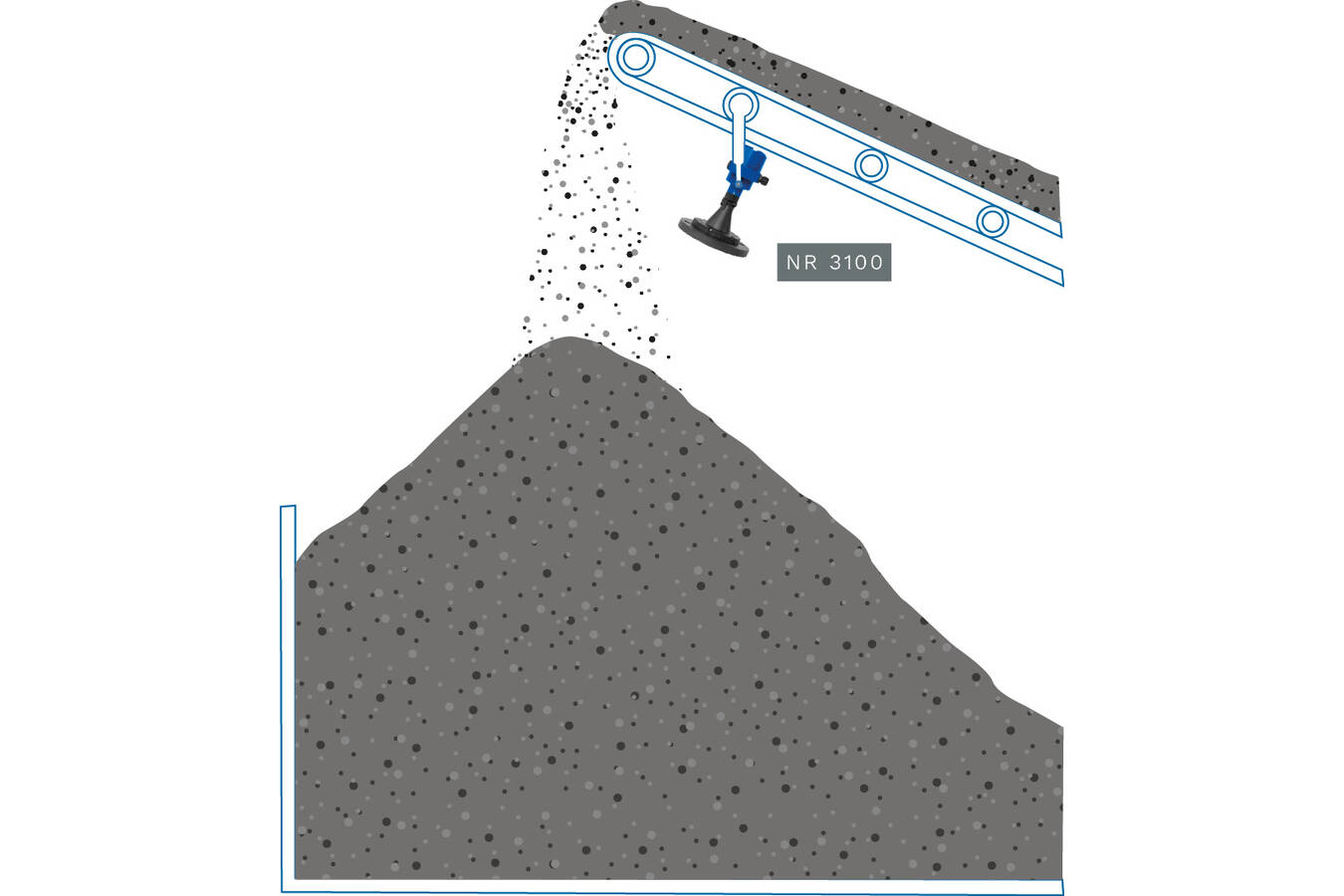

- Non-contact radar measurement (free-radiating radar): In this method, the radar signal is emitted and reflected without direct contact with the medium. UWT’s NivoRadar® models utilise this principle for liquids and bulk solids in silos, tanks, open containers, or stockpiles. A major advantage is the maintenance-free operation, as there are no mechanical components.

- Guided wave radar (GWR, also known as TDR – Time Domain Reflectometry): The radar signal is guided along a probe or cable that comes into direct contact with the medium. This technology is used in UWT’s NivoGuide® series and is frequently applied in complex applications involving foam, steam, solids, or interface layers.

Non-Contact Radar Measurement

Functionality, Precision, and Reliability for Industrial Applications; Free-radiating level measurement with radar sensors has proven its effectiveness in industries such as chemicals, food, energy, recycling, construction materials, cement, and plastics. It offers the highest measurement accuracy and maximum process reliability. UWT’s NivoRadar® combines precise measurement results with robust performance – ensuring reliable measurements even under extreme conditions.

How Does Radar Measurement Work?

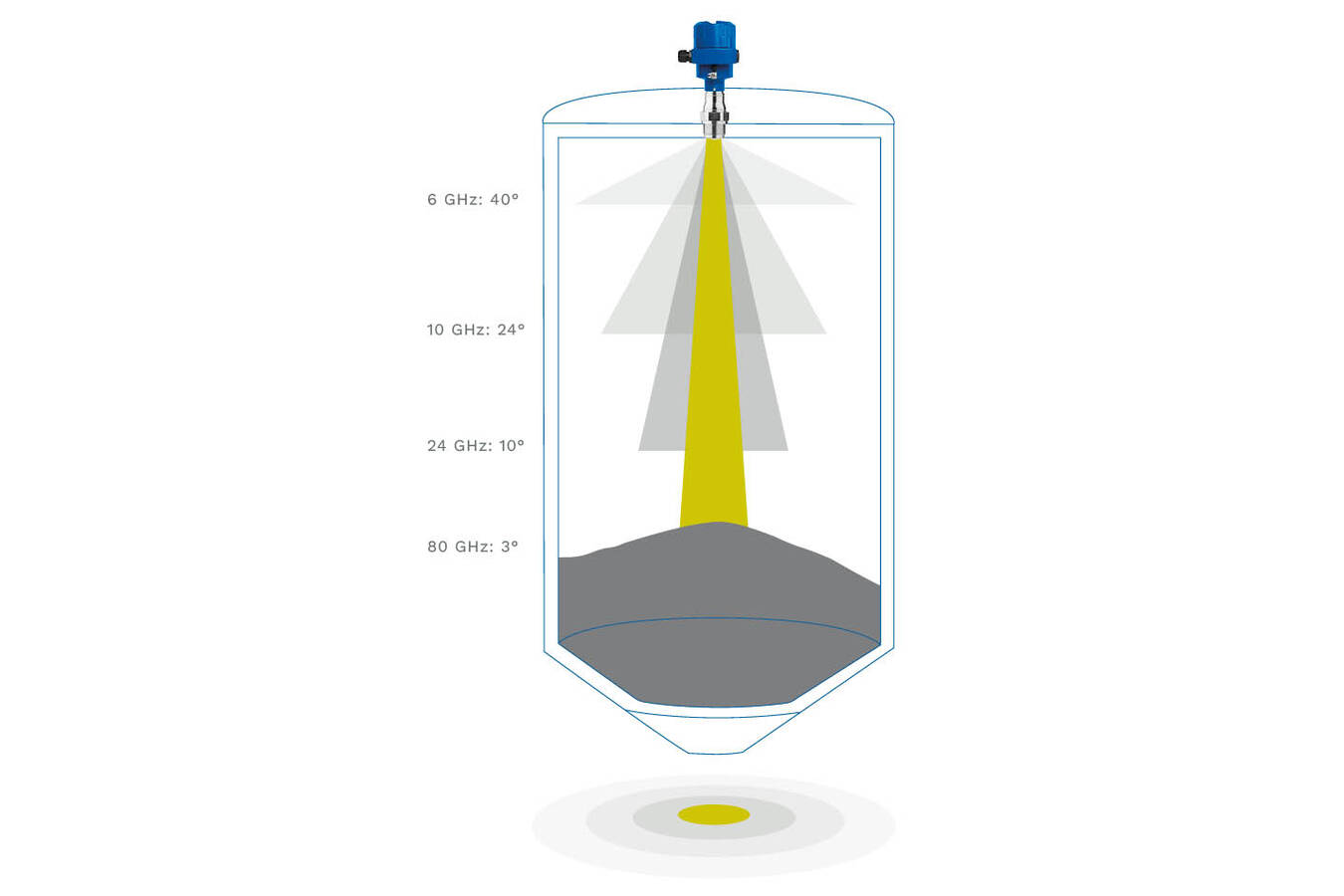

Radar sensors use electromagnetic waves for precise level detection. A high-frequency signal is emitted, reflected by the surface of the medium, and received as an echo. The time taken for the signal to travel to the surface and back determines the exact fill level.

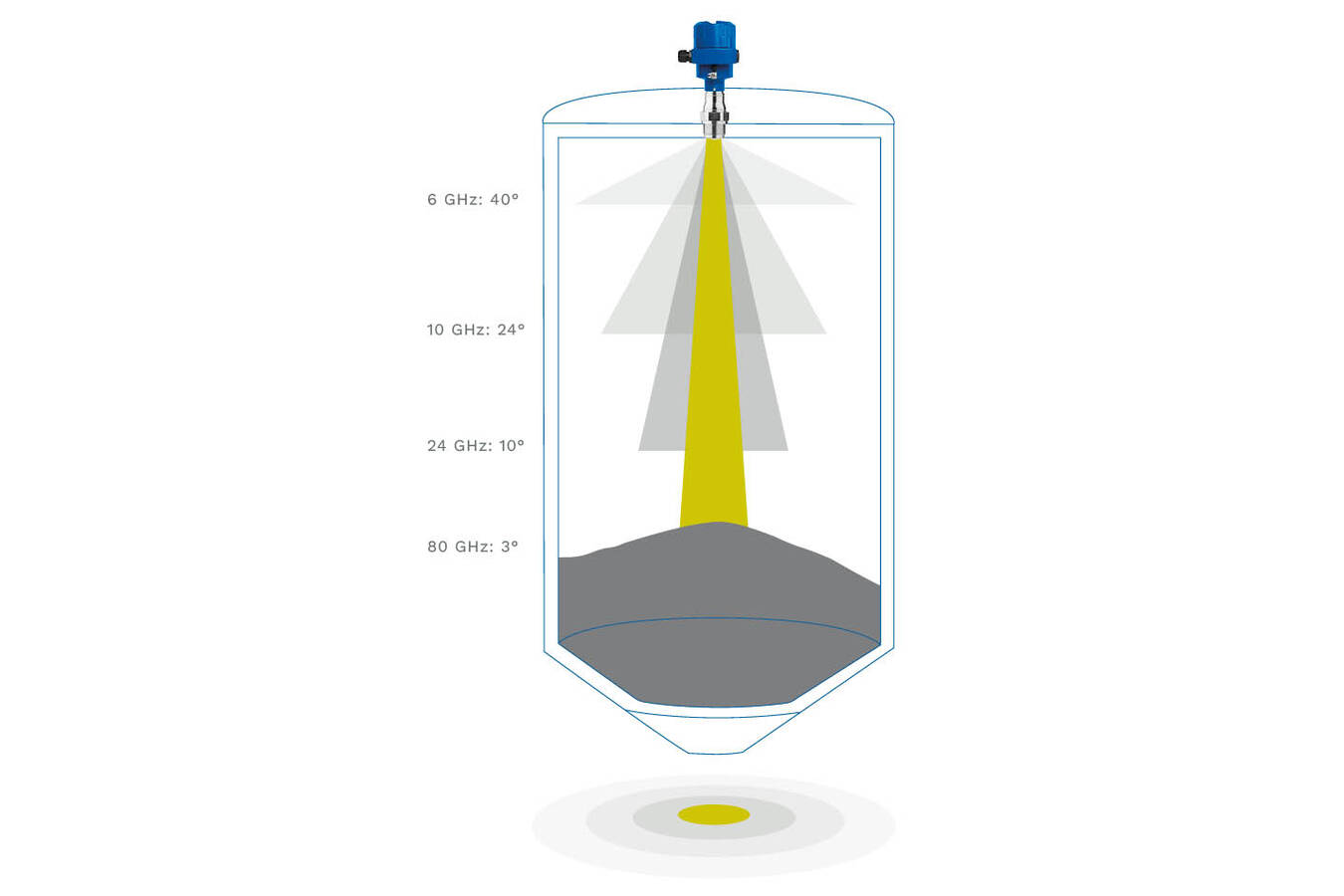

Thanks to 80 GHz technology, the signal is highly focused, with a narrow beam angle of just 3°. This allows for precise measurements even in confined tanks or complex installations. The beam width is directly influenced by frequency and antenna size: the higher the frequency, the more focused the signal. Antennas with a small beam angle can also be installed closer to the tank wall, reducing interference from agitators or other internal structures.

Various models NivoRadar®

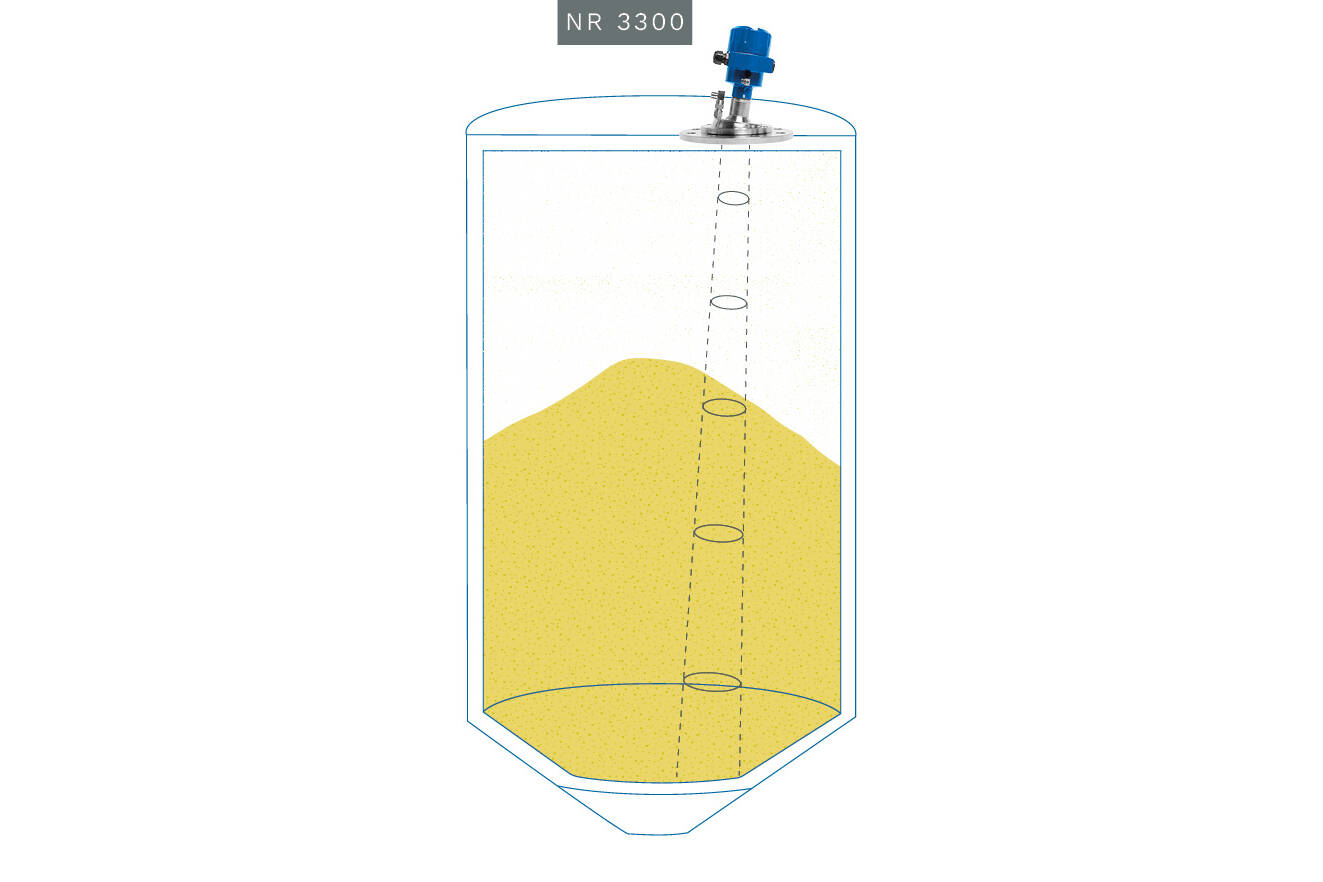

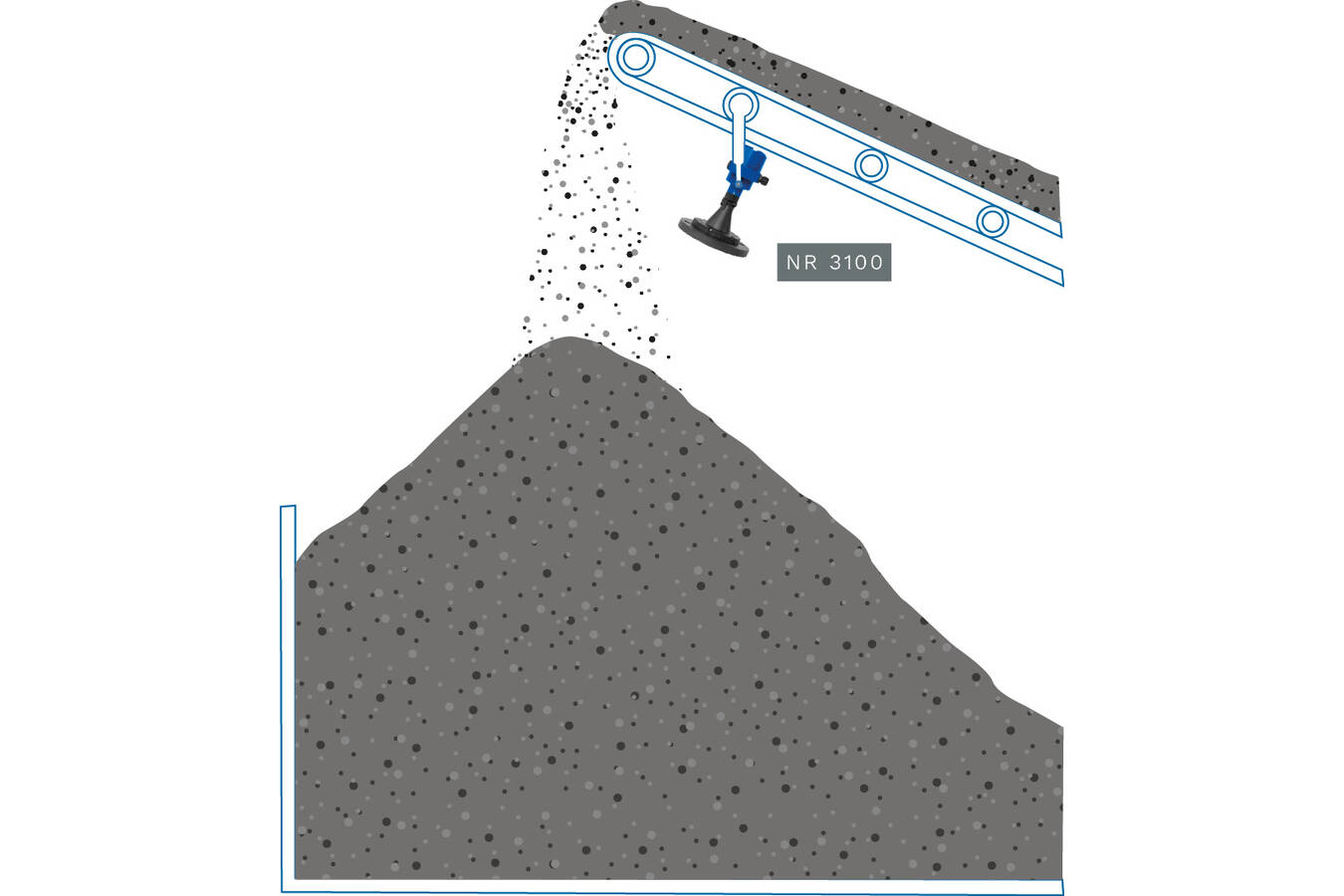

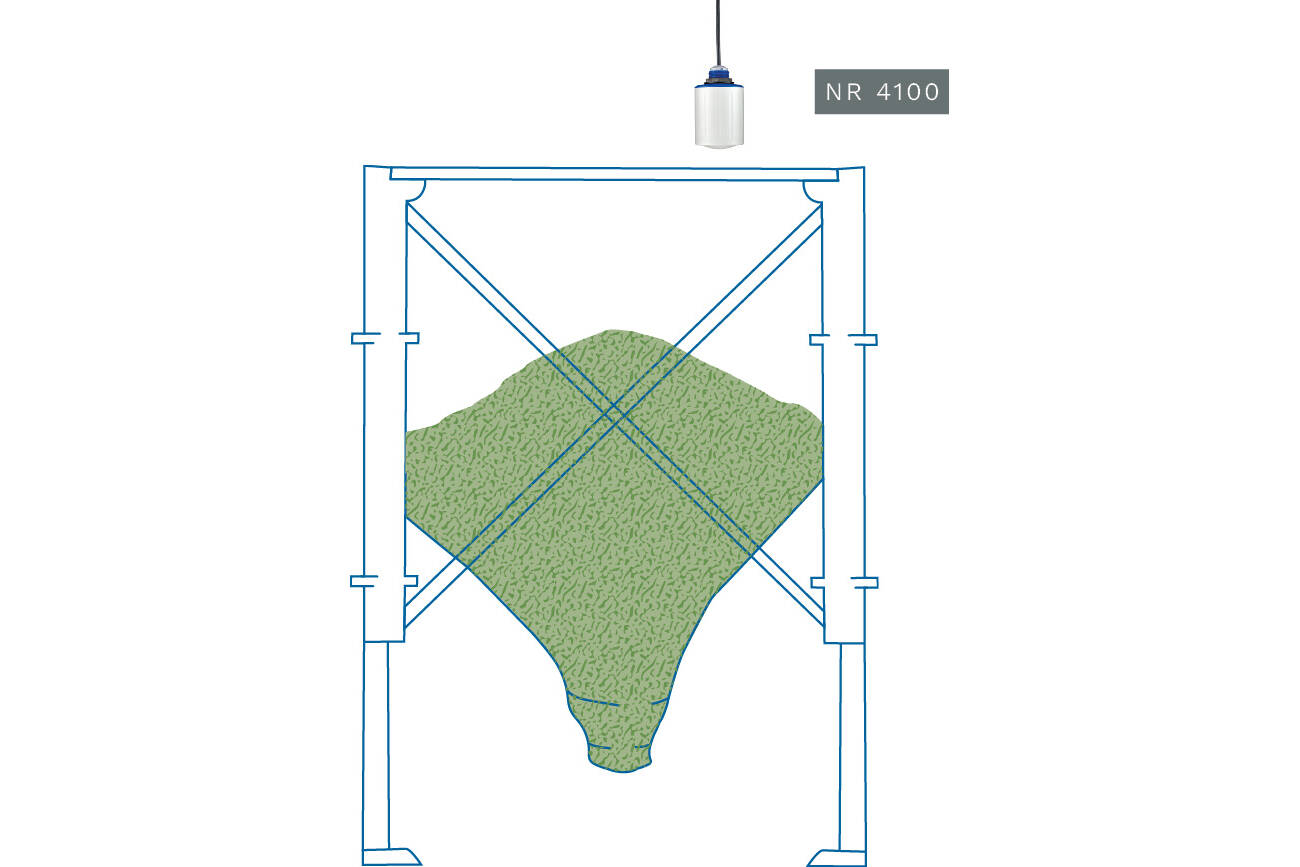

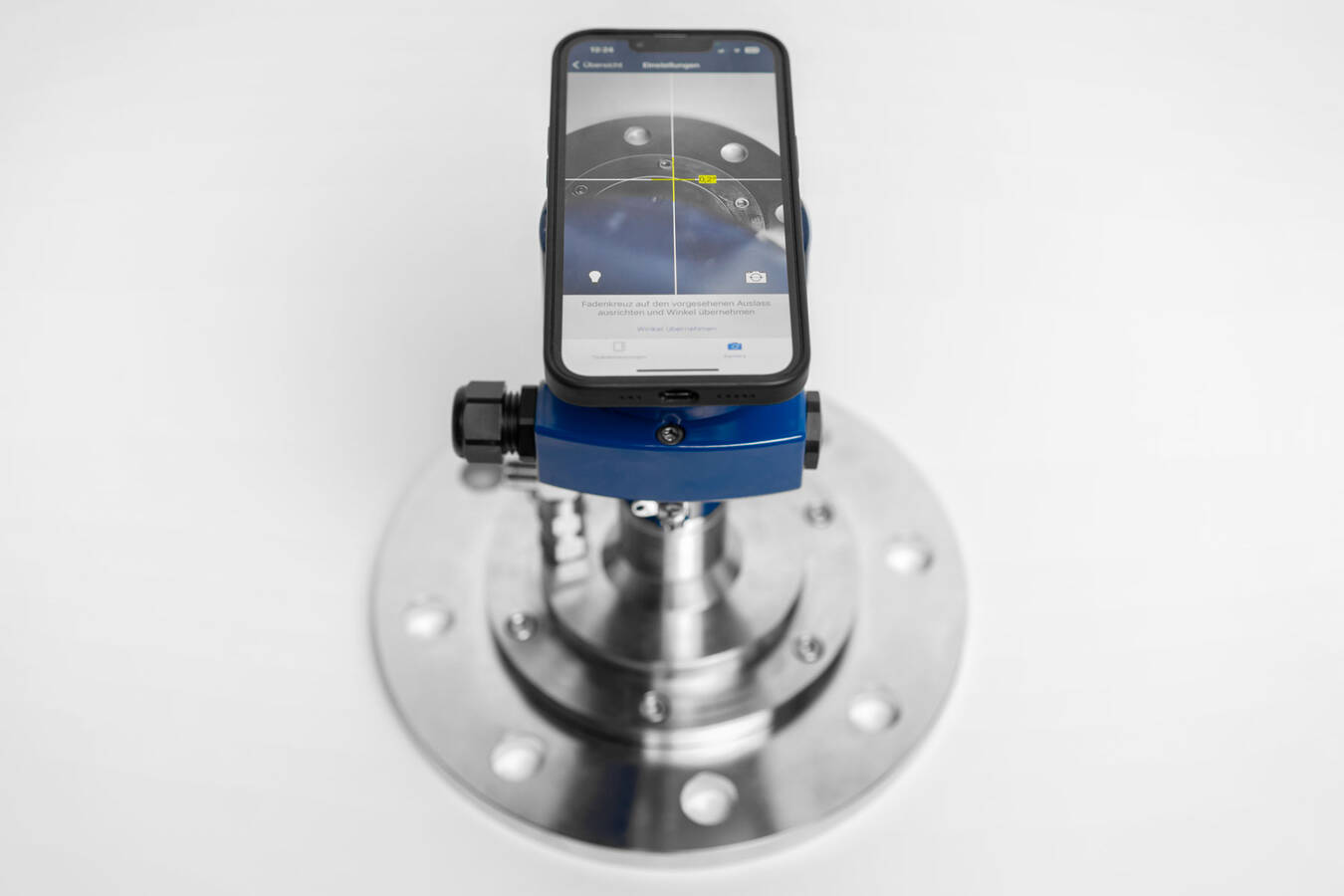

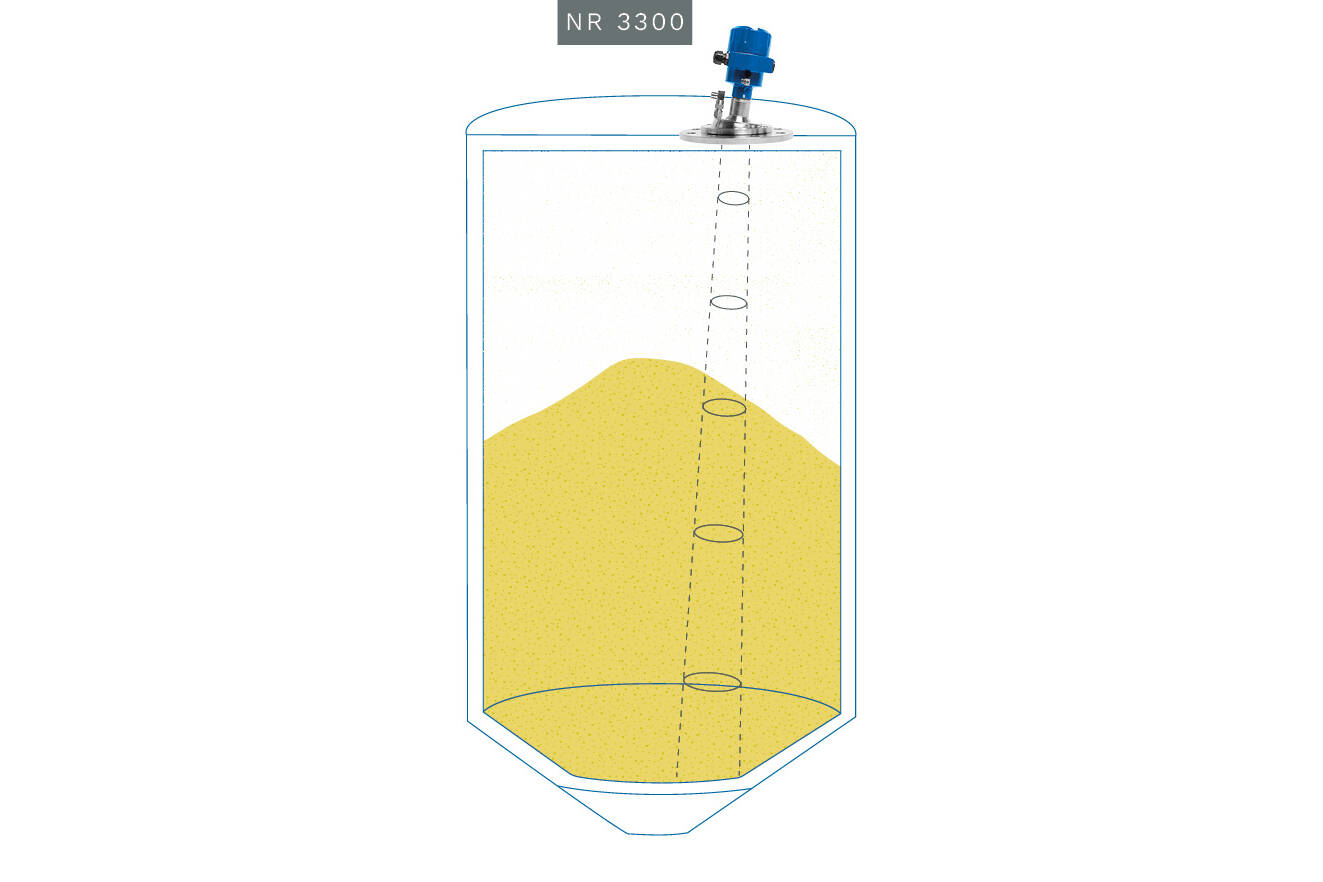

- NivoRadar® - NR 3: High-Precision 80 GHz sensor for bulk solids in silos and containers. Even in high dust conditions or on uneven surfaces, it provides reliable measurement results. The narrow 3° beam angle enables measurements up to 120 metres. An automatic lens cleaning system ensures self-cleaning functionality. Configuration is simple via a clip-on display, UWT LevelApp, or PACTware.

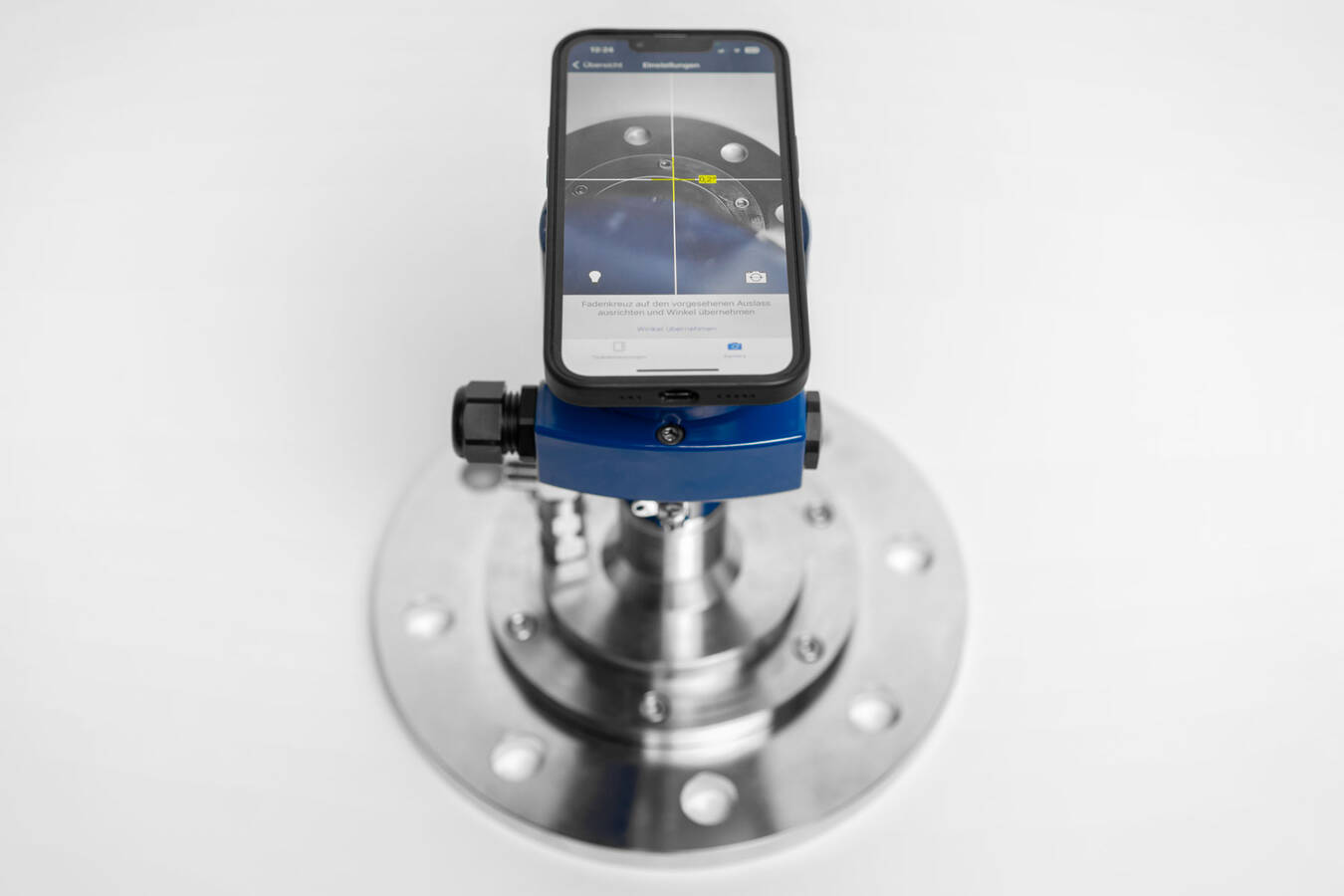

- NivoRadar® - NR 4: Compact FMCW radar sensor for bulk solids and liquids up to 30m. With a 4° beam angle, fast response time, and a robust PVDF housing (IP66/IP68), it is ideal for hazardous areas. Easy installation and operation via the UWT LevelApp.

- NivoRadar® - NR 7: A cost-effective 80 GHz sensor for liquids and bulk solids up to 15 metres. It features an 8° narrow beam angle, fast response time, and a robust PVDF housing (IP66/IP67). Ideal for small containers and ATEX zones, with wireless configuration available via the UWT LevelApp.

- NivoRadar® - NR 8: A versatile radar sensor for liquids in process and storage tanks, including chemicals and oils. It maintains high precision, even with moving surfaces or turbulent processes. With a narrow 3° beam angle and a measuring range of up to 120 metres, it delivers accurate results.

Various antenna options, including a PTFE-encapsulated and a hygienic antenna, enable use in sensitive environments. The robust stainless steel horn antenna is suitable for high-temperature and high-pressure applications. Easy configuration via a clip-on display, UWT LevelApp, or PACTware.

Advantages of Non-Contact Level Measurement

- Highest Measurement Accuracy: Precise results with an accuracy of ±2 mm, even under challenging conditions.

- Non-Contact Operation: No wear and tear caused by mechanical stress on the measured medium.

- Ideal for sensitive applications: Easily suitable for processes with high hygiene and cleanliness requirements.

- Resistant to Process Conditions: Dust, steam, foam, or temperature fluctuations do not affect performance.

- Minimal Dead Zone: Accurate detection even in fully filled tanks.

- Easy Installation & Operation: Compact design enables quick mounting, with intuitive commissioning via display or UWT LevelApp.

- Low Maintenance & Future-Proof: Reduced operational downtime and long-term process security thanks to advanced high-frequency technology.

Typical Applications of NivoRadar®

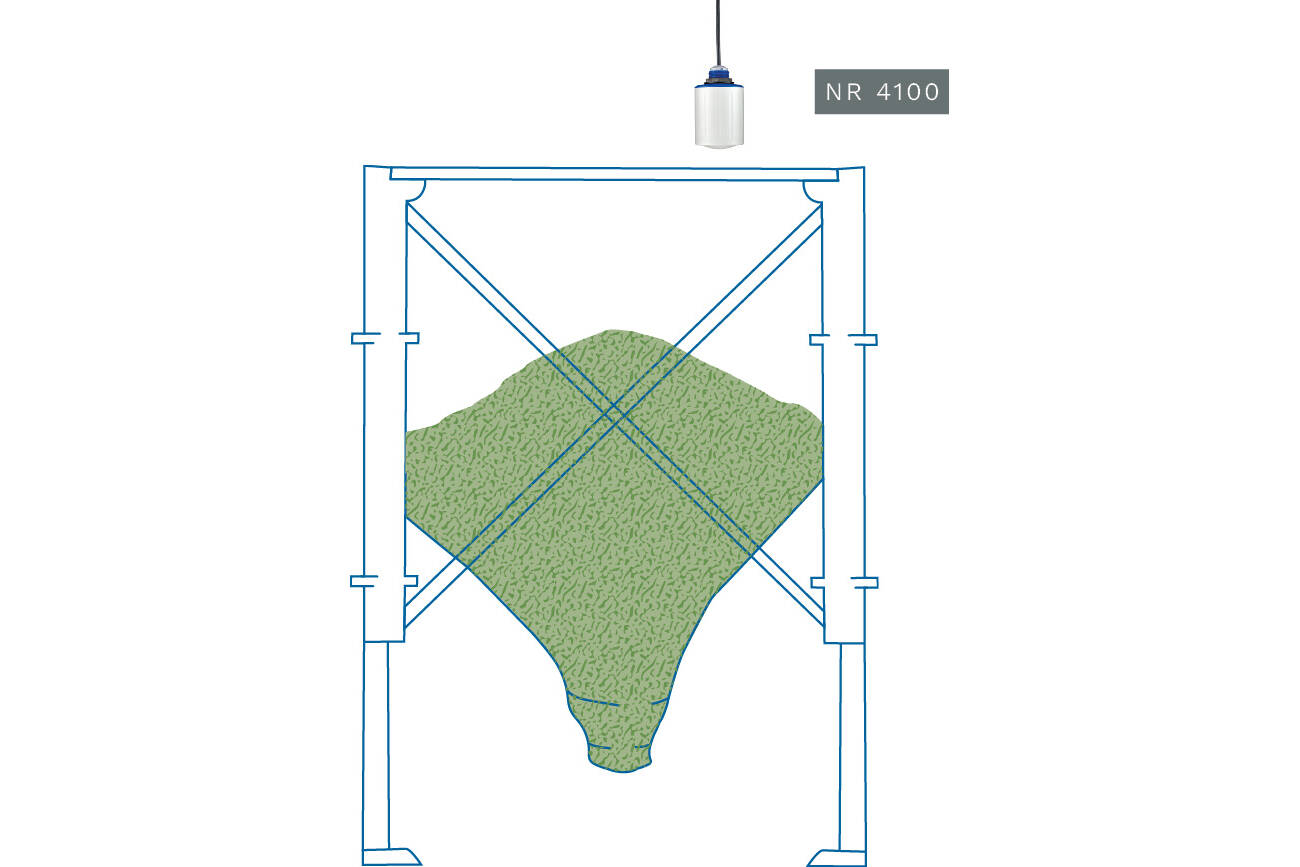

- Bulk Solid Measurement in Silos: Reliable monitoring, even in dusty environments or with uneven surfaces.

- Liquid Measurement in Tanks and Containers: Accurate readings despite moving surfaces or dynamic processes.

- Hazardous Areas: ATEX-certified sensors ensure maximum safety.

- Process Monitoring: Non-contact level measurement for various industries, unaffected by aggressive media, high temperatures, or pressures.

- Hygiene-sensitive applications: Ideal for use in the food or pharmaceutical industry – non-contact, easy to clean, and process-safe.

Radar Technology for the Future

The advanced 80 GHz radar technology found in NivoRadar® provides businesses with a future-proof, precise, and low-maintenance solution for reliable level measurement. With continuous innovation and smart sensor integration, this technology ensures high operational safety and process optimisation.