In data centres, uptime is crucial. Uninterrupted operation is essential for all critical services. A key factor in maintaining this, often underestimated, is a standardized and reliable identification system for all infrastructure components. Discover how a leading automotive manufacturer revolutionized their operations and minimized risks by implementing a robust identification system. Learn how Brady’s innovative labeling solutions delivered clearer infrastructure, fewer errors, and rock-solid reliability.

The Challenge: Reducing Downtime Risks

Datacentre professionals constantly aim for high service levels. A significant risk to continuous operation is human error, particularly disconnecting the wrong cable. The complexity of modern datacentres, with dense cabling, makes this risk higher. To minimize the risks of incorrect cable disconnection, clear, reliable, and consistently applied labels for racks, servers, and cables are vital.

The Solution: Durable Labels and Efficient Processes

One of important automotive manufacturer recently addressed this by implementing a comprehensive identification approach. They used industrial-grade labels designed for datacentre demands. These labels, like Brady’s B-425, B-427, and B-461, use specially developed materials and adhesives, ensuring they stay attached even to curved surfaces like UTP cables.

Beyond the labels, the solution included advanced design and printing capabilities.

- [AHREF**SW**brady.eu/software/brady-workstation-apps?sfdc=701UK00000NDvErYAL&utm_campaign=pwid-datacentres&utm_medium=web-advertorial&utm_source=recyclingportal&utm_content=case-standardised-datacentre-identification**Brady Workstation label design apps] let technicians create and customize labels easily from various devices.

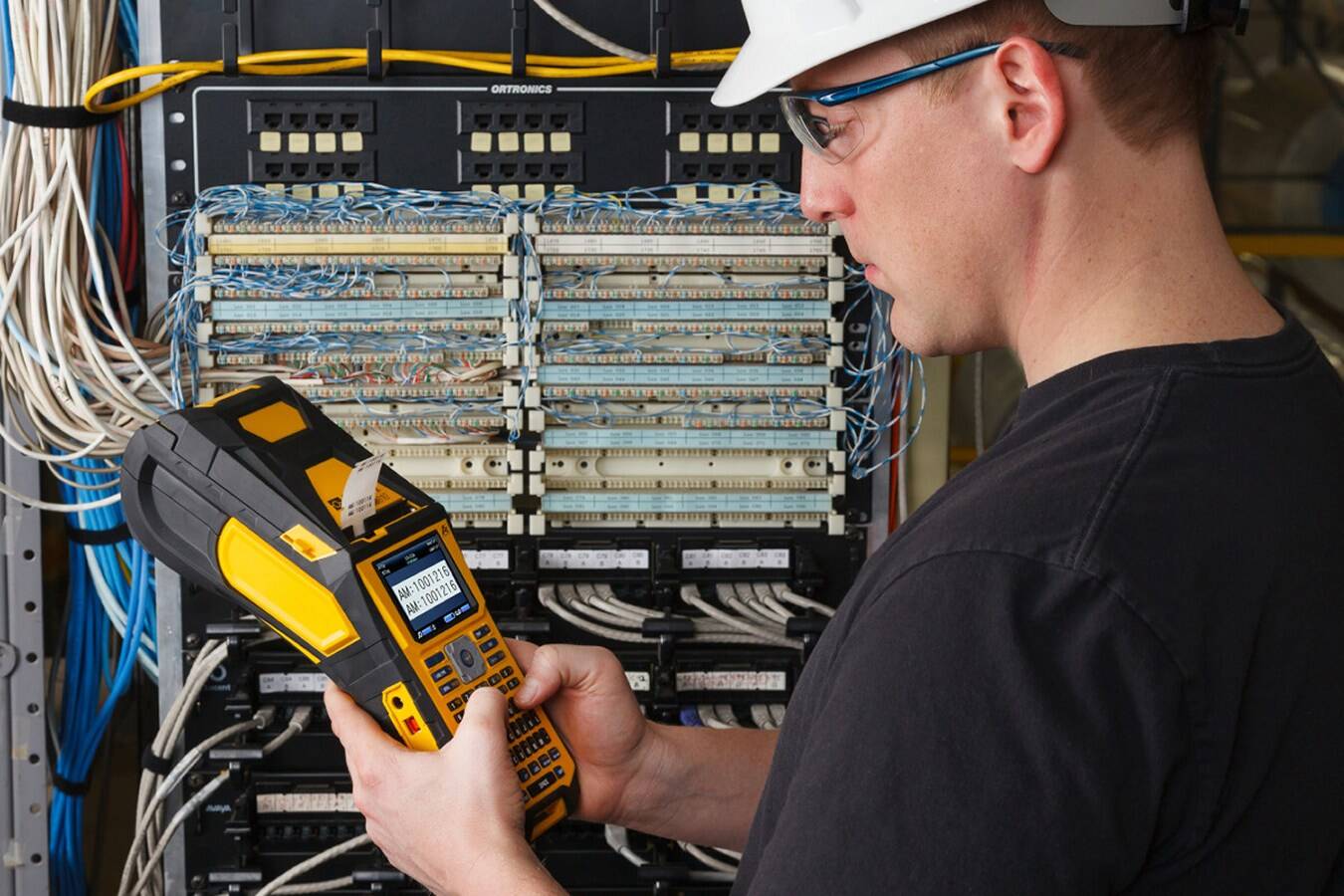

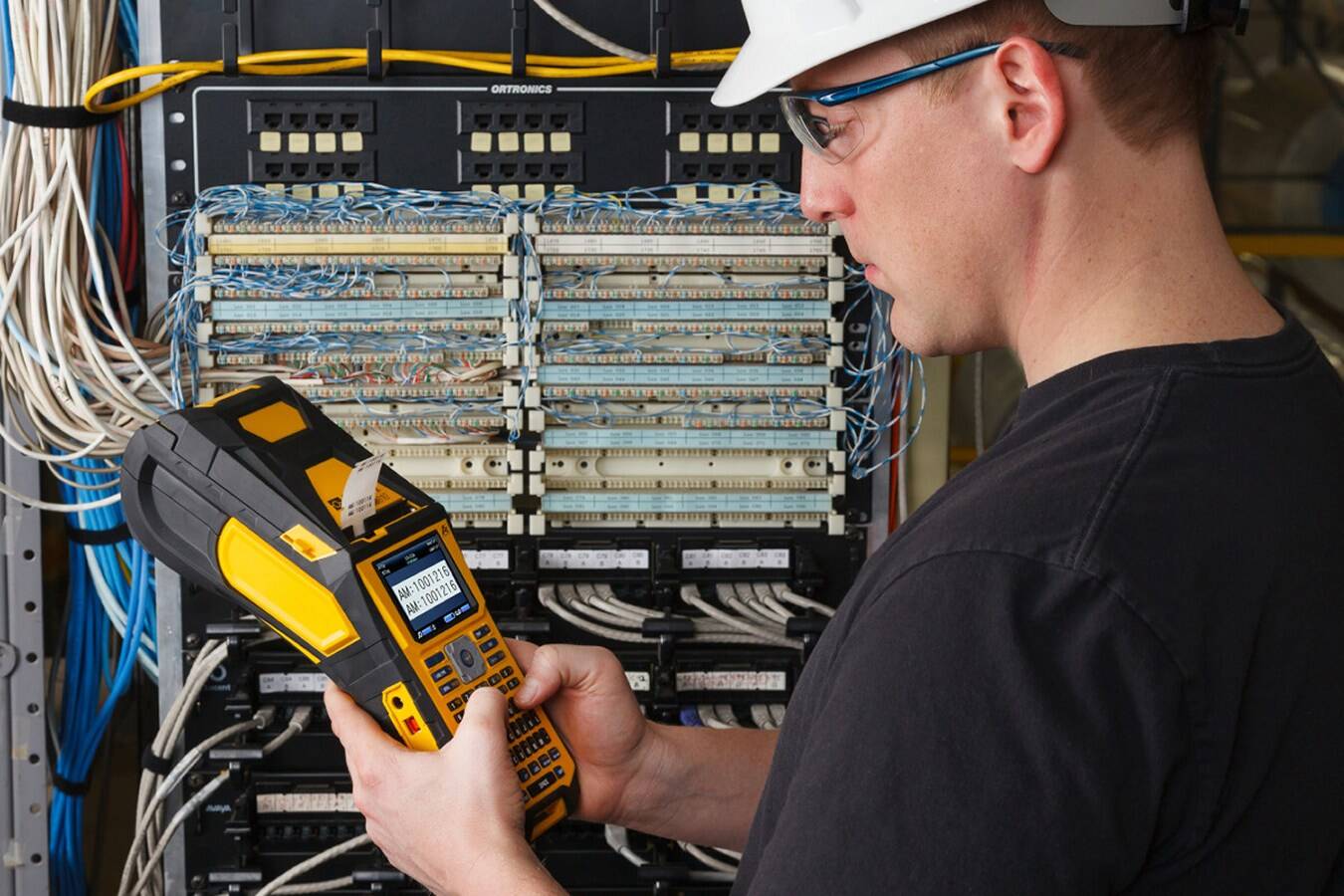

- For on-site printing, the handheld [AHREF**SW**brady.eu/label-printers/m610-label-printer-qwerty-eu-pid-m610-qwerty-eu?sfdc=701UK00000NDvErYAL&utm_campaign=pwid-datacentres&utm_medium=web-advertorial&utm_source=recyclingportal&utm_content=case-standardised-datacentre-identification**M610 Label Printer] is practical.

- For larger volumes, the [AHREF**SW**brady.eu/label-printers/bradyprinter-i7100?sfdc=701UK00000NDvErYAL&utm_campaign=pwid-datacentres&utm_medium=web-advertorial&utm_source=recyclingportal&utm_content=case-standardised-datacentre-identification**BradyPrinter i7100 Industrial Label Printer] provides efficient batch printing.

Crucially, the implementation included on-site consulting to help standardize labels and support the datacentre’s overall identification strategy. This ensured the new labeling system integrated smoothly with existing operations.

Results: Preventing Errors and Enhancing Uptime

Brady labels and identification solutions have delivered clear benefits. By ensuring labels remain securely attached, the risk of cable patching mistakes has significantly decreased. This directly contributes to improved data centre uptime and service levels. Additionally, the streamlined process for designing, printing, and applying labels has made standardization practical and easy to implement.

In an industry where uptime is crucial, a reliable identification system is not just good practice; it’s one of the fundamental elements of operational resilience.

Discover how Brady can optimize your data centre’s uptime.

[AHREF**SW**brady.eu/industry-expertise/datacom-telecom-identification?sfdc=701UK00000NDvErYAL&utm_campaign=pwid-datacentres&utm_medium=web-advertorial&utm_source=recyclingportal&utm_content=case-standardised-datacentre-identification**Find out more about dedicated identification and labelling solutions for datacenters]

Ready to enhance your datacentre’s reliability?

[AHREF**SW**brady.eu/general/brady-emea-locations?sfdc=701UK00000NDvErYAL&utm_campaign=pwid-datacentres&utm_medium=web-advertorial&utm_source=recyclingportal&utm_content=case-standardised-datacentre-identification**Speak with a Brady expert to discuss your data centre’s specific needs.]