PolyFlow has been specifically designed for the concepts and principles of fluidization, ensuring better performance and a longer operating life compared to conveyor products that are merely used in fluidization applications.

Traditional air flow fabrics are usually of a solid woven construction. This type of material can have “hot spots” caused by uneven air flow through the weave, leading to lack of fluidity and reduced capacity. PolyFlow gives an even air distribution to ensure a good cushion for a consistent flow with virtually no abrasion wear.

Unlike solid woven belts, PolyFlow does not need to have the edges heat or silicone sealed to prevent air loss, and the needle felt material is easy to cut and drill for flange fitting.

The design and construction offer several significant advantages over solid woven fabrics:

Key Advantages of PolyFlow Fabric

- Uniform and Consistent Airflow: The needled construction ensures even air distribution, preventing ”hot spots” and guaranteeing consistent flow.

- No Fraying or Sealing Required: Unlike solid woven belts, PolyFlow will not fray when cut or drilled, eliminating the need to heat or silicone seal the edges, which speeds up and simplifies installation.

- Stretch and Mildew Resistant: PolyFlow does not require stretching during installation and won’t continue to stretch afterward, preventing blockages. It is also rot and mildew resistant, unlike solid woven cotton fabric.

- Minimal Particulate Infiltration: The standard material has extremely small pore openings, with an average of just 7 microns. Another version averages only 4 microns, preventing particulate from infiltrating the fabric, which avoids flow retardation and excessive wear, thus lengthening belt life.

- Better Air Seal: The construction and smooth surface of PolyFlow naturally provide a better seal, allowing caulking to work more effectively and ensuring no air leaks, which can be difficult to achieve with the irregular surface of solid woven fabrics.

- Ideal for Flexibility: PolyFlow is easy to cut and drill for flange fitting, and its design makes it ideal for bends and unusual shapes.

- Extremely Efficient and Economical: It is an extremely efficient material with low operating and economical purchase costs.

Proven Applications and Technical Specifications

Extensive testing by Spoornet Transwerk (South African Railways) for cement applications has demonstrated that PolyFlow provides consistently good flow rates and shows no particulate infiltration. The material is a solid partner for powder and bulk handling components.

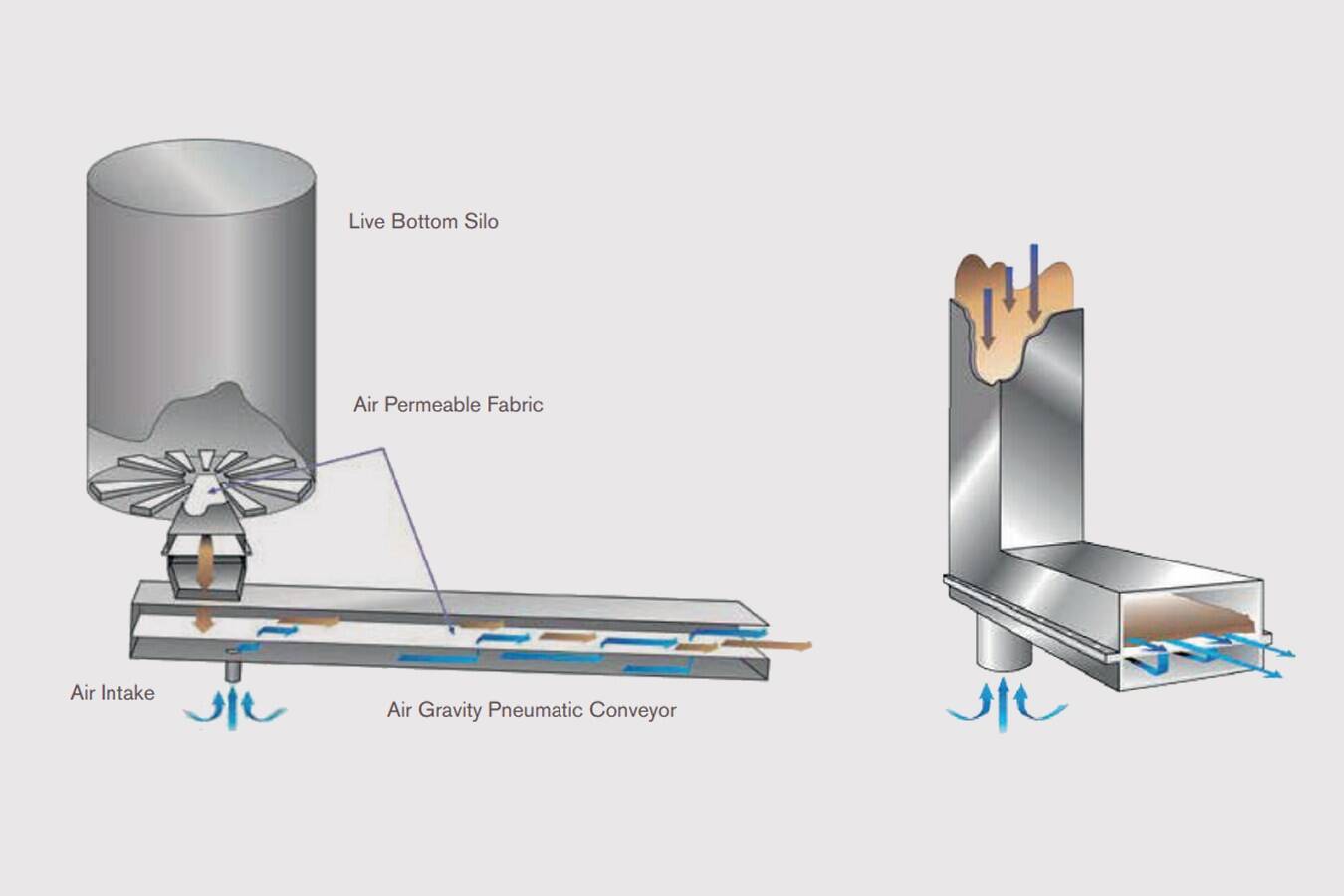

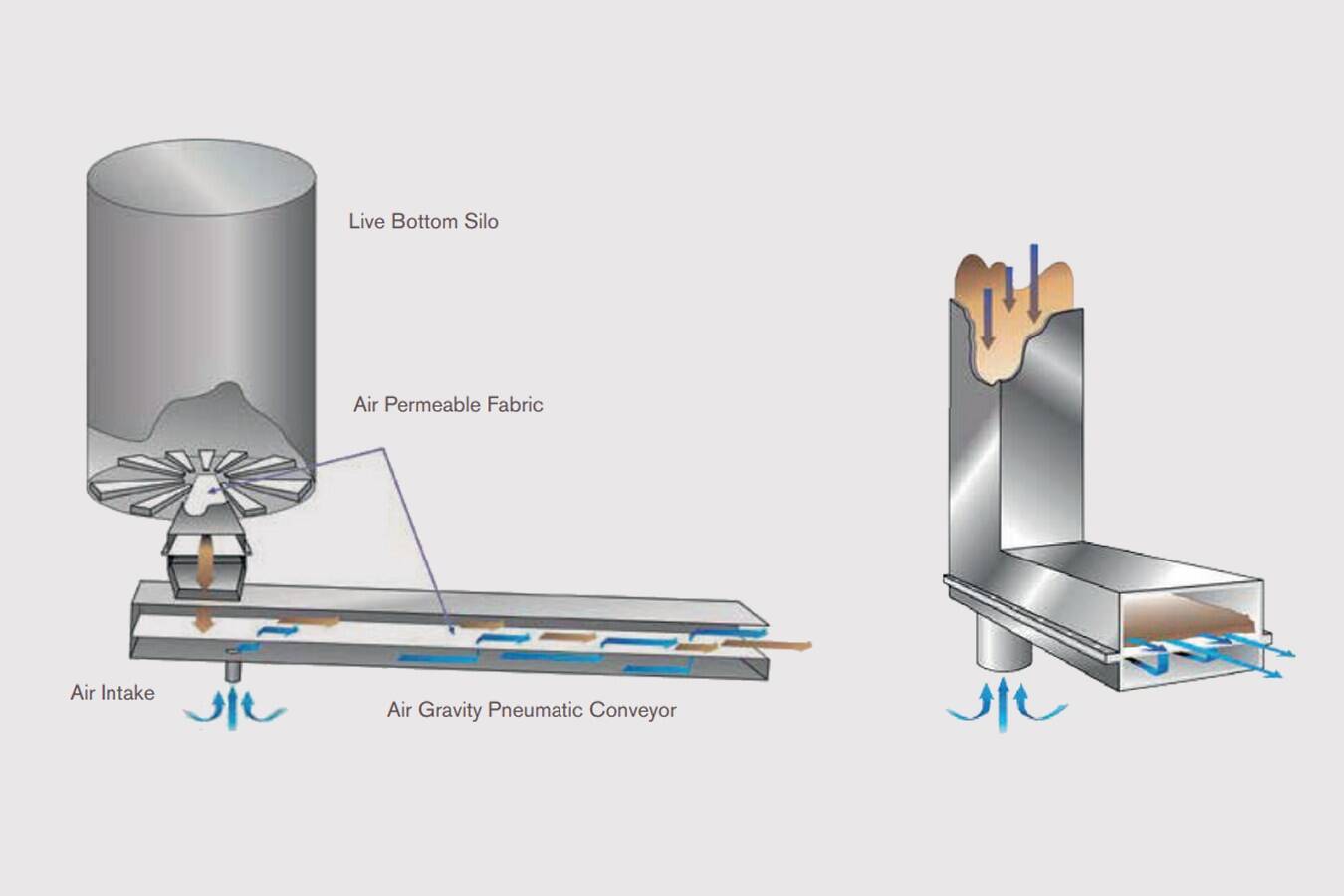

PolyFlow is the ideal membrane for air gravity pneumatic conveyors and live bottom silos. It is widely applicable across numerous industries for materials including: Cement, Alumina, Fly Ash, Silica Sand, Kaolin, Barite, Flour, Pumice, Resins, Chemicals, Wheat, etc.

The standard PolyFlow material has a very small aperture opening of just 7 microns and is designed to operate at up to 150°C, but a special high heat (250°C) version is available to order, as are versions with different water permeabilities.

For more technical details or advice regarding the PolyFlow Air-Permeable Polyester Fabric, please contact Muller Beltex