Why IIoT and AI are now making a difference

As a manufacturer of highly specialized filling and packaging systems, GREIF-VELOX knows that efficiency today comes from connectivity + availability + reliability. Production data, which was previously available only selectively, is now recorded in real time, transmitted securely, and made usable—for operational decisions on the shop floor as well as for strategic improvements in operations.

Customer benefits at a glance:

- Real-time monitoring of entire lines and critical components

- Early maintenance recommendations (predictive maintenance) before costly downtime

- Continuous optimization of cycle times, quality, and resource utilization based on live data

- Secure, scalable architecture, suitable for globally distributed machine parks

VeloXpert + ei³: Integrated data solution

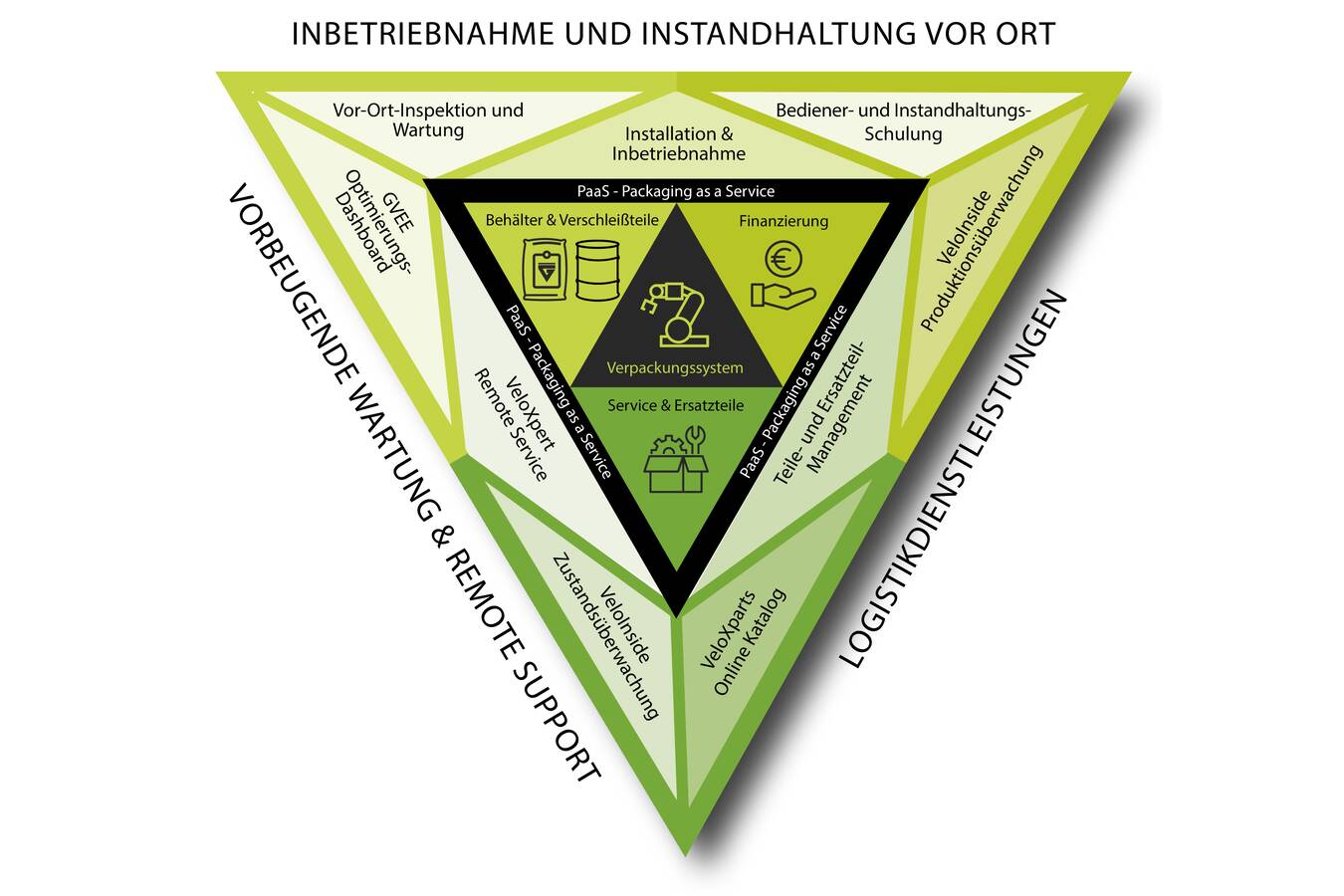

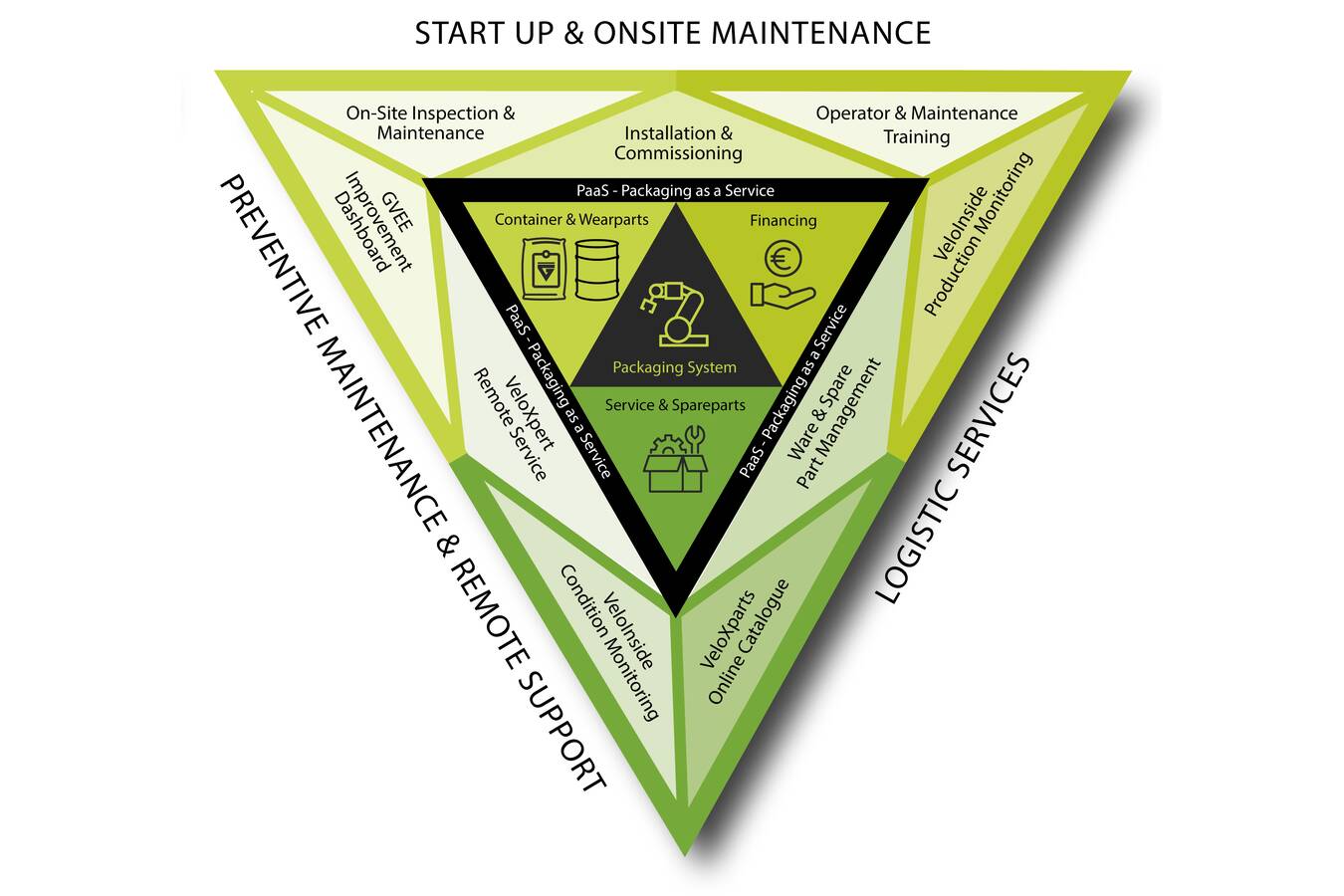

At the heart of the digital services is VeloXpert, the service program from GREIF-VELOX. In combination with the secure gateways and data platform from ei³, this creates an end-to-end solution – from data acquisition to decision-making:

- Structured data acquisition: Machine and process data are read out in a standardized format.

- Visualization in the VeloInside Dashboard: Clearly prioritized KPIs, trends, and warnings.

- Action guidelines: Data flows directly into maintenance, fine-tuning, production planning, and spare parts management.

The result: high uptime, lower costs

And teams making decisions faster and based on facts. Predictive maintenance and GVEE: making efficiency measurable. The partnership enables anomalies to be detected early: increasing idle times, limit violations, or creeping quality losses are visible in the dashboard and automatically evaluated. Maintenance becomes predictable and unplanned stops are minimized.

Overall Equipment Effectiveness

Central to this is Greif-Velox Equipment Effectiveness (GVEE) – a key performance indicator system based on the established OEE (Overall Equipment Effectiveness) and expanded to include process-specific factors for powder and liquid filling. This provides a more accurate picture of actual plant performance, including material- and production-specific influences (e.g., flow properties for carbon black, silica, pigments, or viscosity for liquids).

Advantages of GVEE logic:

- More meaningful than generic OEE models

- Faster root cause analysis in case of deviations

- Targeted measures instead of generic “best practices”

Security first: Zero-trust architecture

ei³ relies on a zero-trust architecture. This means that every access is consistently verified, every data stream is encrypted end-to-end, and segmented rights and role models prevent unauthorized access – even in heterogeneous machine environments with systems from different manufacturers and years of manufacture. For operators with high compliance requirements, this is a key enabler for scaling digital services.

Practical relevance for bulk solids & liquids

- The solution addresses typical challenges in the chemical, petrochemical, raw materials, food, and battery materials industries:

- Powder filling (e.g., carbon black, silica, pigments, starch, fibers): More stable bag weights, less dust, reproducible cycle times, lower complaint rates.

- Liquid filling (barrels, IBCs, canisters): Correct fill quantities, reduced rework, better planning reliability for shift and raw material use.

- Globally distributed fleets: Uniform KPIs, benchmarking between locations, faster scaling of best practices.

Quick to get started, scalable and expandable

- Gateway installation on the line, secure connection via the ei³ platform

- Data modeling based on GVEE logic

- Rollout of the VeloInside dashboard including KPI definition and alarm rules

- Enablement of teams (maintenance, production, quality) with clear guidelines for action

- The architecture is modular: start a pilot cell, validate results, expand the range of functions – all the way to company-wide fleet control.

Conclusion

The combination of GREIF-VELOX packaging expertise and ei³’s secure IIoT/AI technologies creates a new level of quality in data-driven production management. Operators benefit from higher availability, predictable maintenance, and demonstrable productivity gains – with maximum data security.