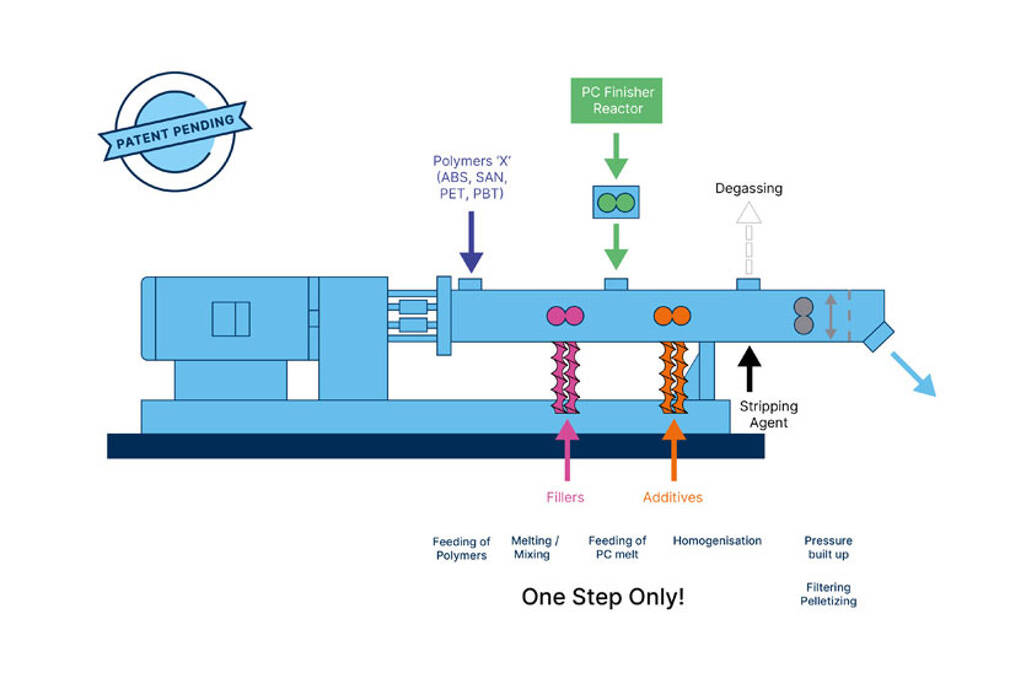

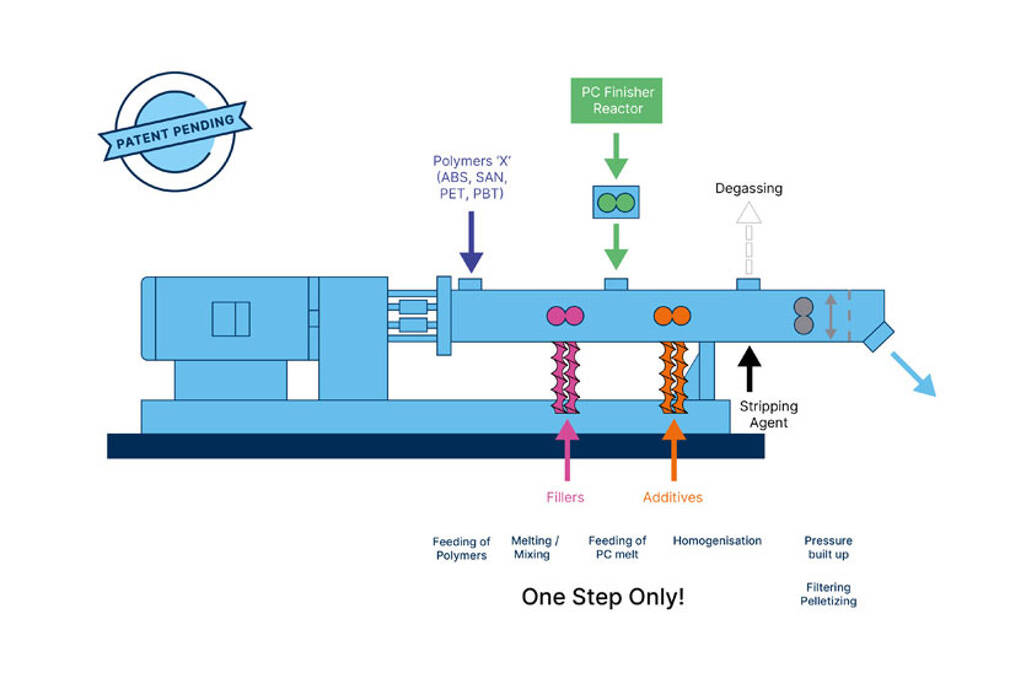

Innovative One-Step Process for Melt Compounding

The new technology integrates the polycarbonate melt directly from the polymerization reactor into a Coperion ZSK twin screw extruder. This eliminates several traditional production steps to streamline the entire process. The collaboration focuses on enhancing efficiency and flexibility within the bulk solids and plastics industries.

Key Advantages of the Direct Compounding Technology

- Significant reduction in energy consumption by avoiding reheating

- Operational cost savings of up to 1 million USD per 100 kta

- Lower capital expenditure due to reduced infrastructure needs

- Faster market response times through flexible formulation adjustments

- Elimination of intermediate pellet storage and conveying systems

Sustainability and Economic Efficiency

By removing the need for secondary extrusion and complex material handling, the system provides a more sustainable approach to non-phosgene polymerization. The process ensures high-quality output while optimizing resources.