Sesotec at IFFA 2022; X-ray inspection on a new level

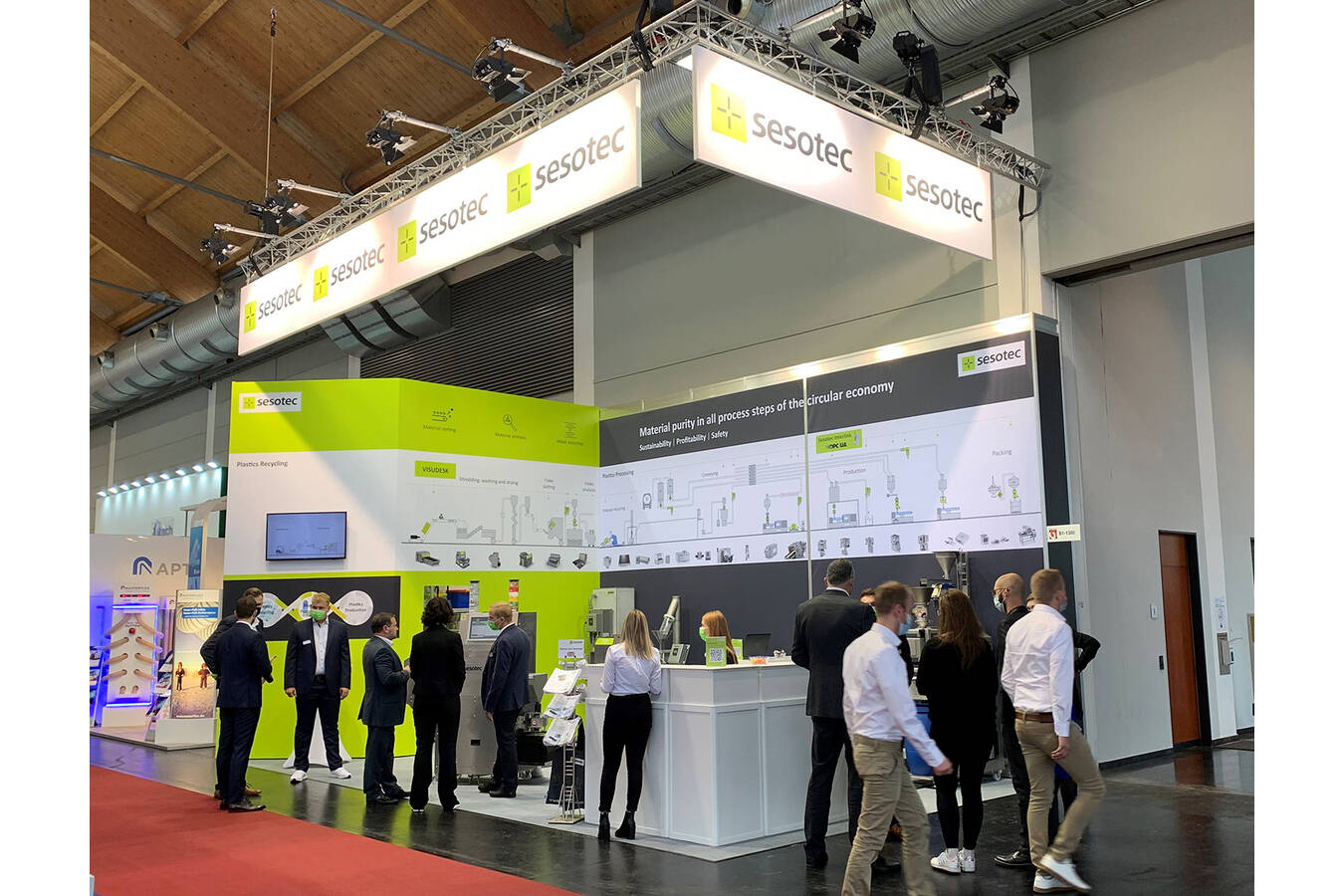

IFFA hall 11.0, booth C51: visitors can expect an extensive portfolio of foreign object detectors for every application in the food industry Schönberg, May 2022

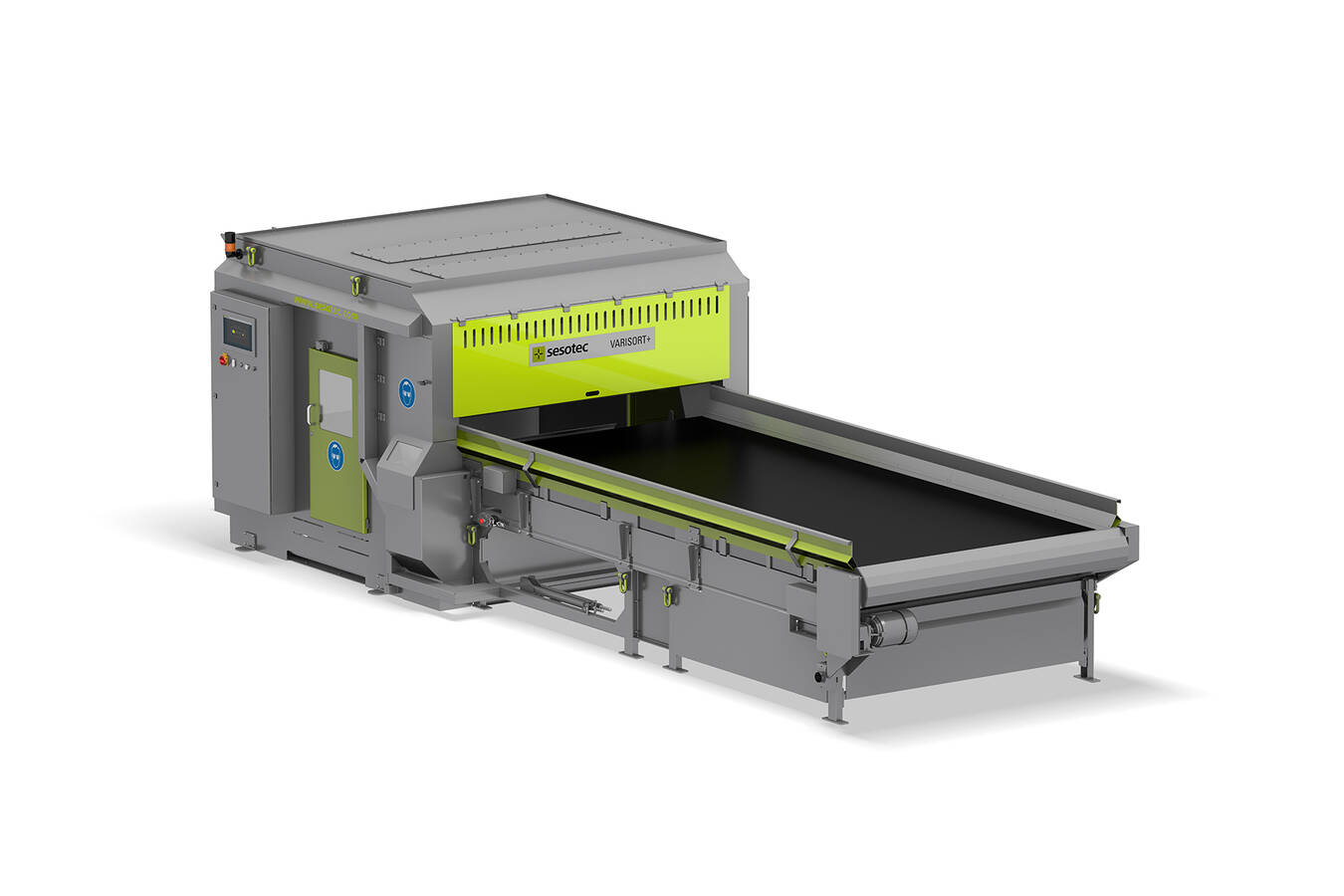

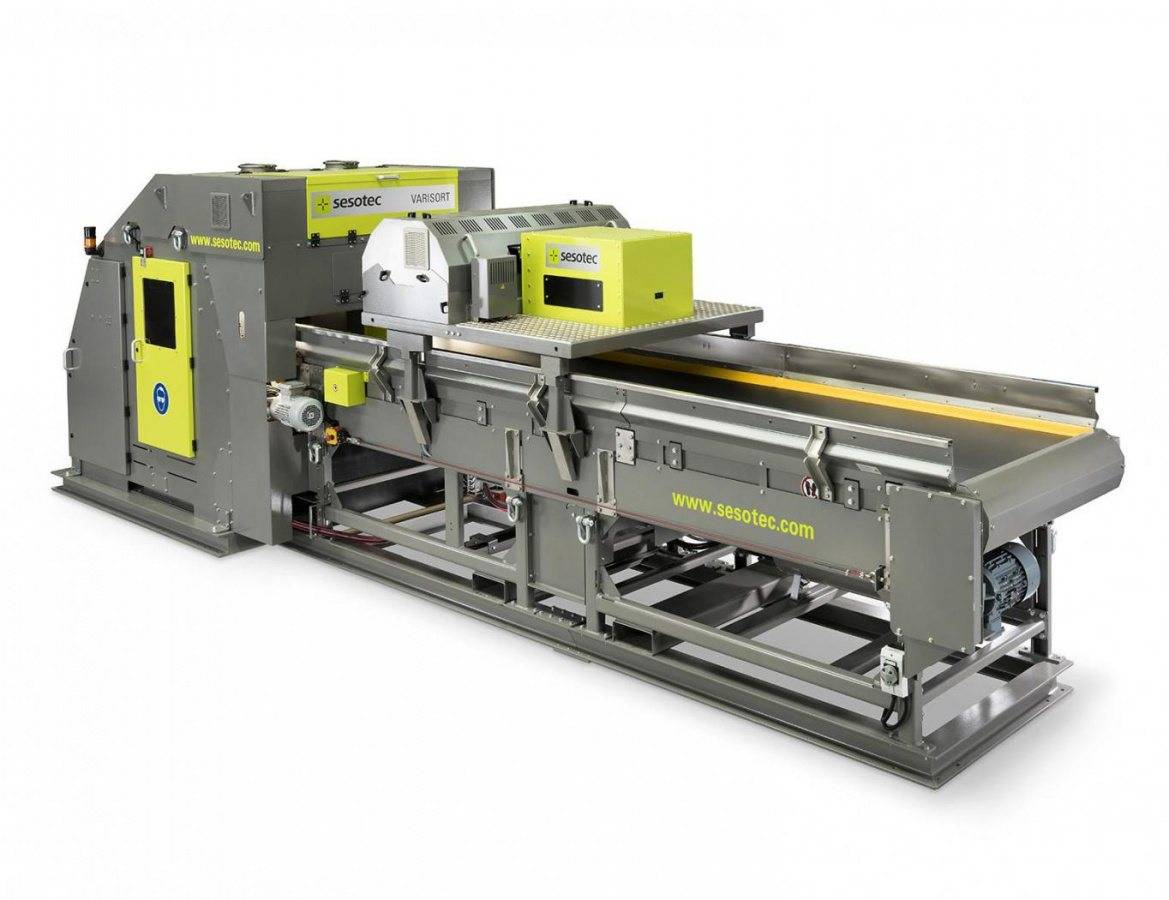

Sesotec live at IFFA from May 14 to 19, 2022 in Frankfurt: visitors to the booth in Hall 11.0, C51 can expect an extensive portfolio of foreign object detectors for every application in the food industry. The highlight is the latest generation of RAYCON X-ray inspection systems. Sesotec’s service offerings will be another focus of the trade show.

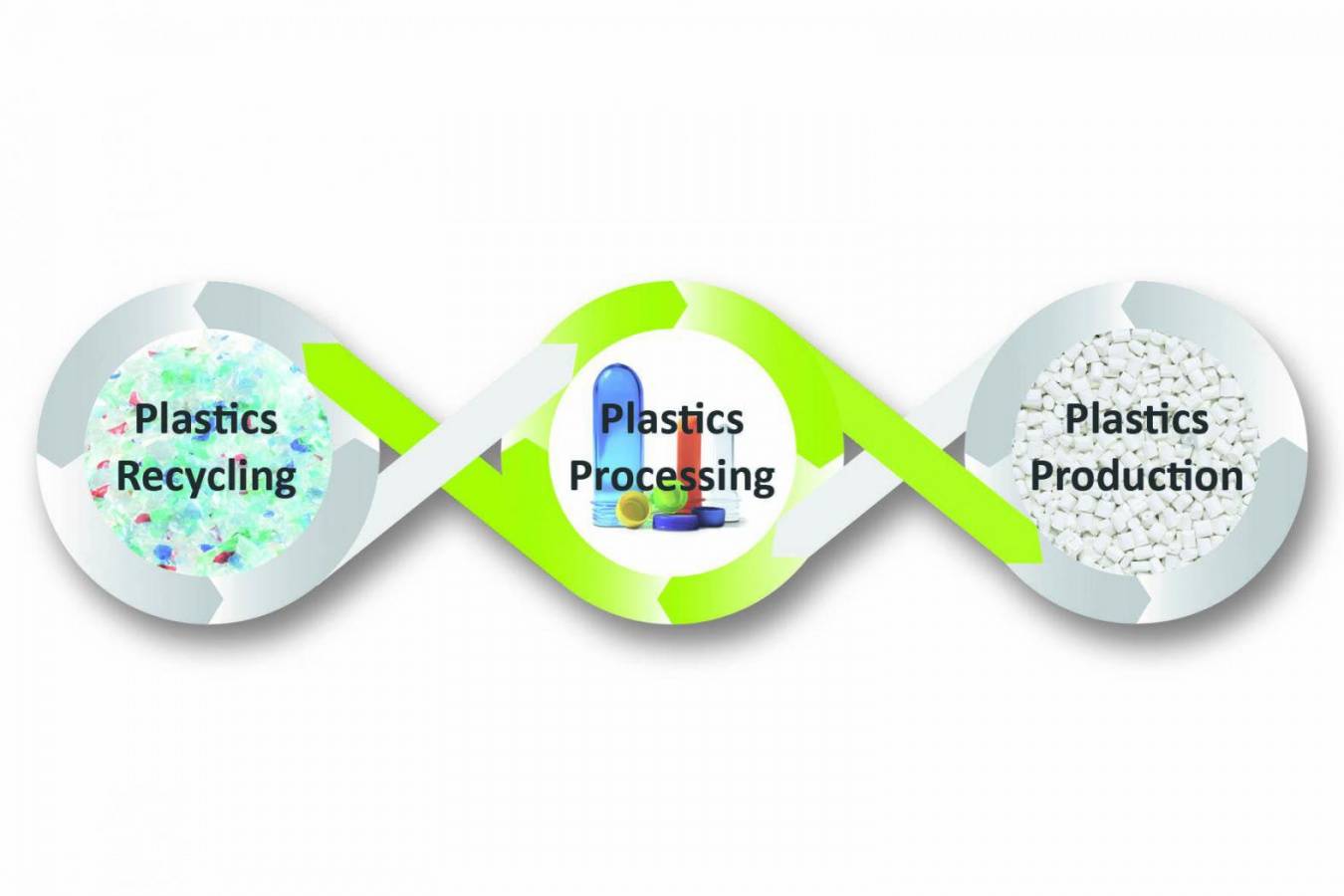

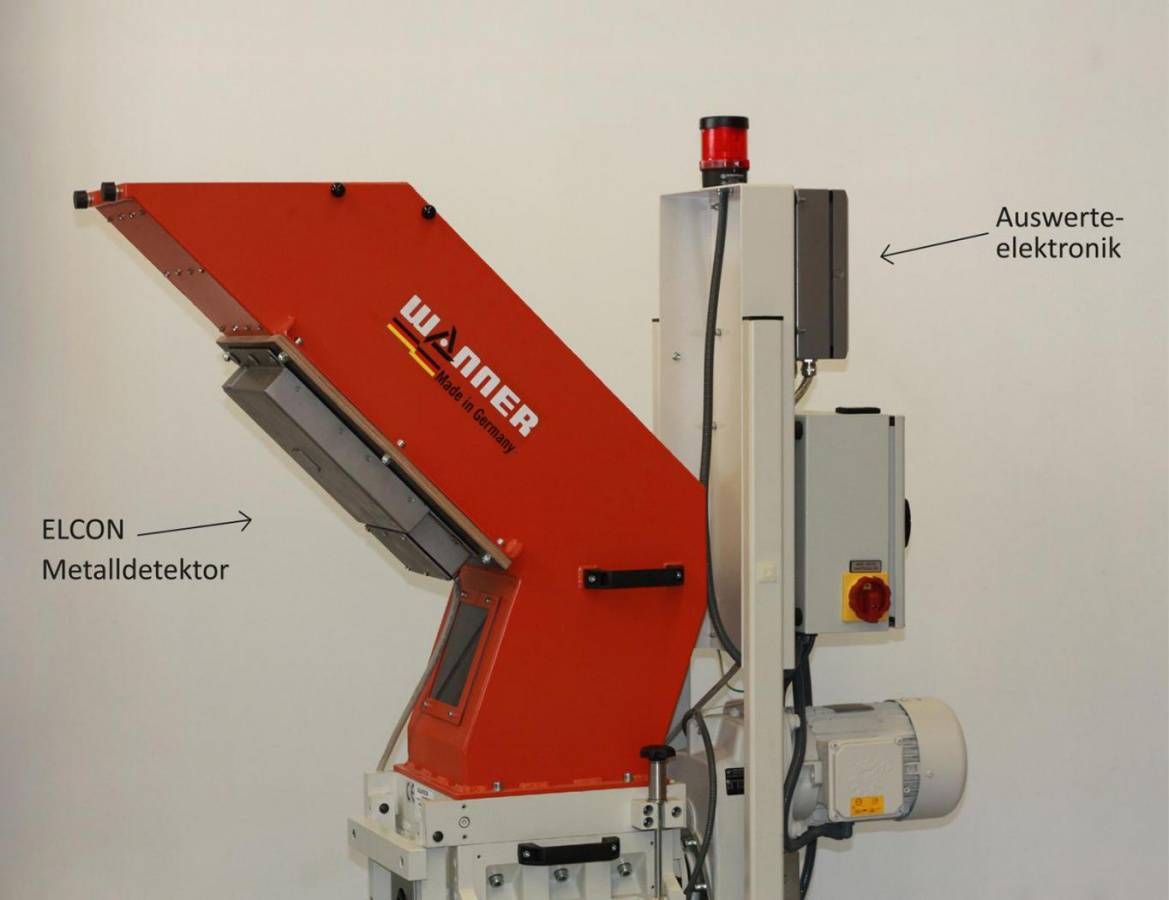

Sesotec has developed the new RAYCON family, which includes entry-level, standard and high-end solutions, according to the ”6 priorities concept”. This concept builds on the main requirements of the food industry for compliance, safety, hygiene, efficiency, operation and service. All systems ensure reliable detection of foreign bodies such as metals, bones, stones, plastics, glass splinters and ceramics, as well as other product defects during food production and processing. Innovative software features in the new ”Bonesdetector”, ”Wirefinder” and ”Glassincreaser” filters specifically