The Compact Lab Companion. Only at NOLL’s.

A pioneering concept for R & D and small-quantity production. As mill or classifier – modules changed in no time. Fines directly filled into sample containers

A pioneering concept worldwide. Only at NOLL’s. Cost-efficient, flexible and user-friendly like no other laboratory system. Ultra-compact and multifunctional. Suitable for almost any product application. Fitted on a mobile cart, equipped as dynamic air classifier or opposed jet mill, the classifier and mill module can be changed in no time. Your ideal companion in the lab.

For almost any product application

The system can be used for R & D, testing and small-quantity production in almost any field: from foodstuffs to metallurgy. The focus is e.g. on the dust removal of metal or polymer powders used for 3D print or surface coating, and on the protein shifting of vegetables, e.g. leguminosae.

Your companion through thick and thin.

Take it with you, anywhere. Fitted on a mobile cart, the lab companion fits through any standard door (200 x 80 cm).

User-friendly, cost-efficient, easy to clean

A pioneering concept in the compact class. With its special, exclusively patented design, NOLL’s latest engineering coup is a standardized while highly flexible performer, cost-efficient to purchase and to operate like no other comparable laboratory system.

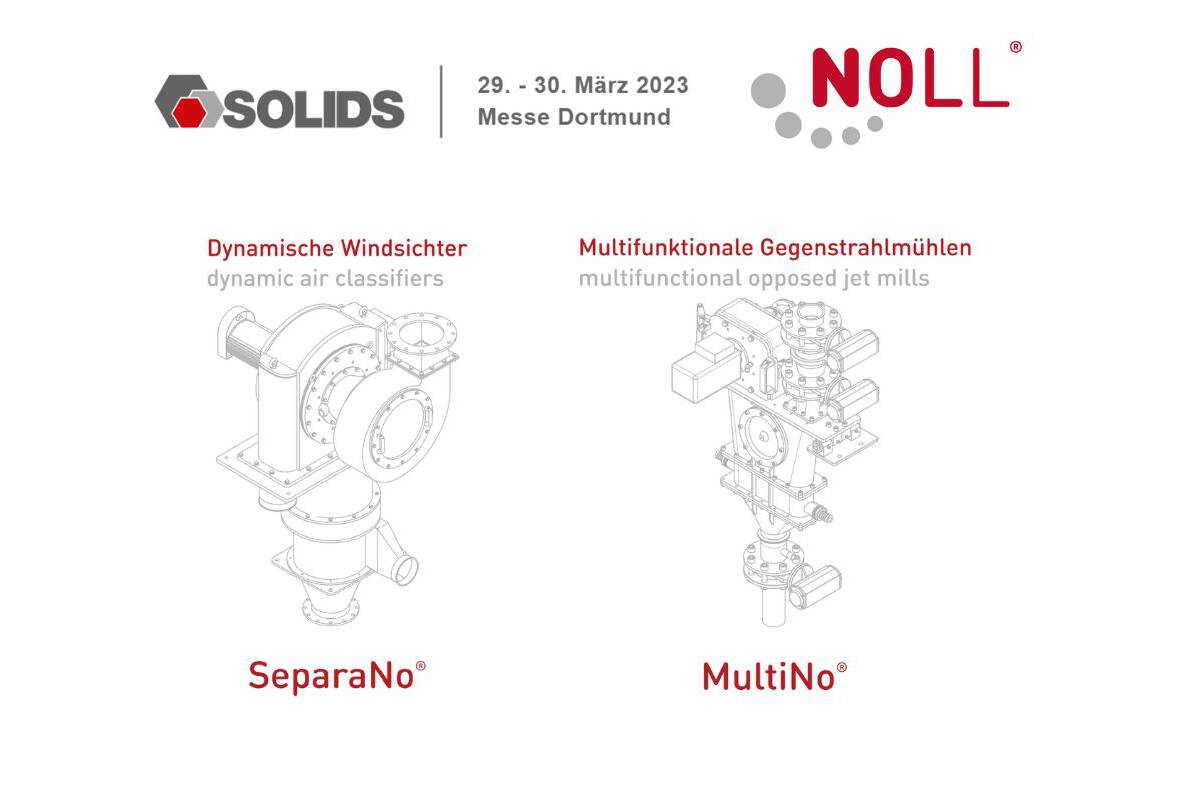

Dynamic air classifier and mill module

Fitted on a mobile cart, equipped as dynamic air classifier SeparaNo® 1050 E or opposed jet mill MultiNo® M/S/M 1050, the lab machine’s classifier and mill modules can be changed in no time. Both system variations allow inert gas operation (argon, nitrogen).

Fines directly filled into sample containers

After fractionizing or milling, the fines are directly filled into sample containers, e.g. standard wide-mouth sample jars, from 0.5 to 5.0 litres capacity, as required. That saves time while minimizing product loss and the potential release of unhealthy dusts. Your sample is immediately ready for storage or can be passed right on to applications testing.

Overall view: 10-inch touch panel

See everything at a glance: your lab companion features an exceptionally large 10-inch touch panel in its housing desk. The users’ manual can be integrated into the panel, making the system work like a smartphone.

Your multifunctional friend in the lab

Fast product changes, a system that saves energy and space: feel how easy lab work can be, in all phases and procedures. Powder testing, the development of new products and small-quantity production become as easy as 1-2-3. Your ideal companion in the lab.

Another genuine NOLL.

With the new lab companion, NOLL laboratory systems continue to set the standards in the compact class worldwide. For three decades, NOLL has been a renowned partner in R & D, cooperating with leading research institutes and universities and supporting the sciences. As a consulting partner in material resources management, or by setting up recycling test laboratories: Working together on pioneering processing systems for green technologies worldwide.

Personally at POWTECH.

Shake hands with the new laboratory system. It is looking forward to your visit: at 4A – 312, the NOLL POWTECH stand in Nuremberg, Germany, September 26-28, 2023.