Innovative custom solution with UWT Radar Sensor

Solution-oriented: Side-mounted radar sensor for continuous level measurement on fly ash hoppers

In a coal power plant in South Carolina, continuous level measurement for fly ash hoppers was required. This specific challenge was effectively addressed by installing a side-mounted guided radar sensor with a 90° elbow shaft. In the energy sector, where environmental protection and safety are of high importance, UWT has once again demonstrated its ability to shine with thoughtful solutions and technical expertise.

The challenge:

Promoting environmental safety through precise level measurement. Fly ash is a byproduct of coal combustion and is an environmental hazard. Coal-fired power plants are obliged to collect this material for disposal or reuse. Precise level measurement is of the utmost importance in this context in order to avoid overfilling, which can lead to safety risks, high cleaning costs and possible fines.

Proven methods, innovative approach

In such situations, free-radiating sensors such as the NivoRadar® 3000 or NivoRadar® 4000 are usually used. However, the special process hoppers in the South Carolina plant presented an unusual spatial challenge, as there was not enough free space at the top for conventional device mounting. This problem required an innovative approach that went beyond conventional vertical mounting techniques

The UWT solution:

NivoGuide® 3000 overcomes spatial challenges with pragmatic, side-mounted radar technology. UWT Level Control LLC, the US subsidiary of UWT, offers the NivoGuide® 3100 with guided wave radar technology as an answer to this problem. This case illustrates the importance of special solutions and UWT’s ability to provide innovative solutions. In contrast to the usual vertical arrangement of radar sensors, where a cable or rod is guided vertically through the container, UWT presented a clever method for this application. By integrating a 90° bent probe extension, it was possible to guide the radar pulse from a horizontally mounted head unit into the container. This flexible solution specifically took into account the limited space at the top of the conical container by enabling the side mounting of the NivoGuide 3100® on the outer wall of the silo. In this way, the spatial restrictions were cleverly circumvented without compromising the accuracy or reliability of the operation.

In the cone-shaped single-chamber silo, there is a process pressure of up to 0.8 bar (11.6 psi). There are no vibrations or electrostatic charges, but there is a dusty atmosphere. The prevailing DK values of 2.0 - 3.0 hardly influence the NivoGuide® radar sensor used with low-frequency microwave pulses in any way, which guarantees a reliable measurement result.

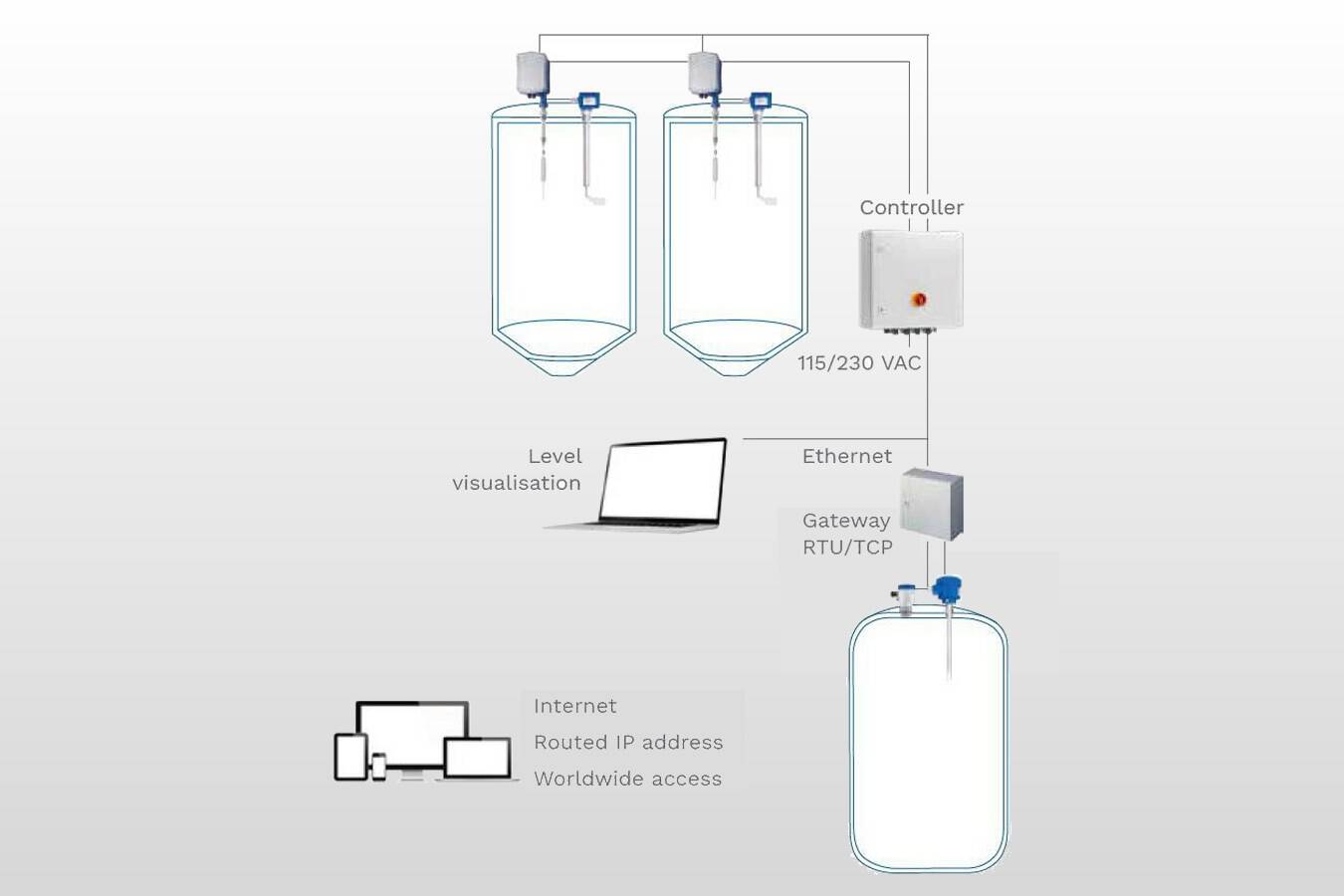

Continuous level measurement

NivoGuide® radar sensors are used for continuous level measurement in liquid and bulk solids applications. The measuring range of up to 75m (246ft) and its high sensitivity from a DK value of 1.5 make them versatile usable in silos, tanks and pipes. The guided wave radar does not contain any moving parts inside the process vessel. The microwaves are emitted at low frequencies, so that even with high dust intensity, no spurious reflection is generated. As a result, the energy content of the microwave can be used exclusively for determining the specific filling level within the storage processes. It is protected against thawing explosions and precisely measures ±2mm even under difficult process conditions. UWT has implemented two series, the NivoGuide® NG 3000 series, which is specially tailored to the needs of solids, and the NivoGuide® NG 8000 for applications in liquids, pastes, foam, slurries, oils as well as for interface measurement. The device versions are each equipped with outriggers that can be individually adapted to the application with rod and cable extensions.

A success story:

Increasing safety and ensuring environmental compliance. Today, the power plant in South Carolina can proudly look back on 12 process hoppers equipped with this customized solution, symbolizing a significant step towards operational efficiency and environmental safety. This endeavor underscores UWT’s commitment to developing versatile, high-performance level measurement technologies tailored to the unique needs of various industries worldwide.

UWT Level Control LLC’s success at the coal power plant epitomizes the company’s core principles - Technology, Performance and Partnership. This solution demonstrates UWT’s ability to innovate and adapt its technologies to customer-specific requirements. The use case presented here offers a convincing answer to the challenges posed by limited installation space.