Every bulk material reacts differently during transport, especially when elevated, and overlooking its specific behavior can lead to premature wear, product degradation, or operational failures.

Product characterization

Product characterization: The foundation of reliable vertical transport. When dealing with fragile, abrasive, greasy, or high-temperature materials, a generic elevator design often proves insufficient. Each material must be assessed for its physical properties to determine the optimal configuration for buckets, belts, and structural elements.

Key parameters to analyze

- Bulk density

- Particle size and shape

- Flow behavior and angle of repose

- Humidity and fines content

- Operating temperature

- Abrasiveness and corrosiveness

These values directly influence not only how the material is discharged from the buckets but also how it interacts with belts, chains, and contact surfaces during elevation.

Laboratory tests and pilot trials

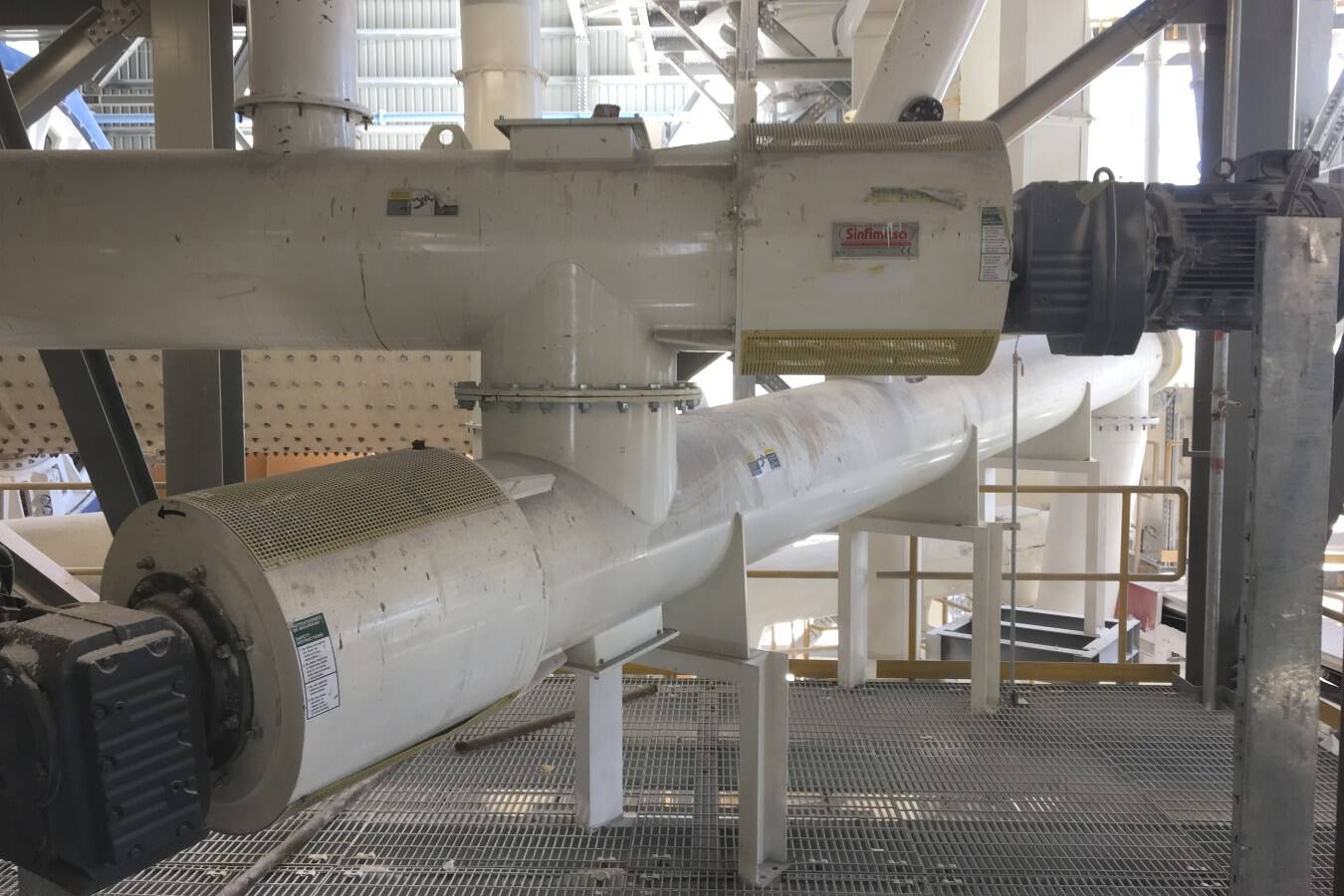

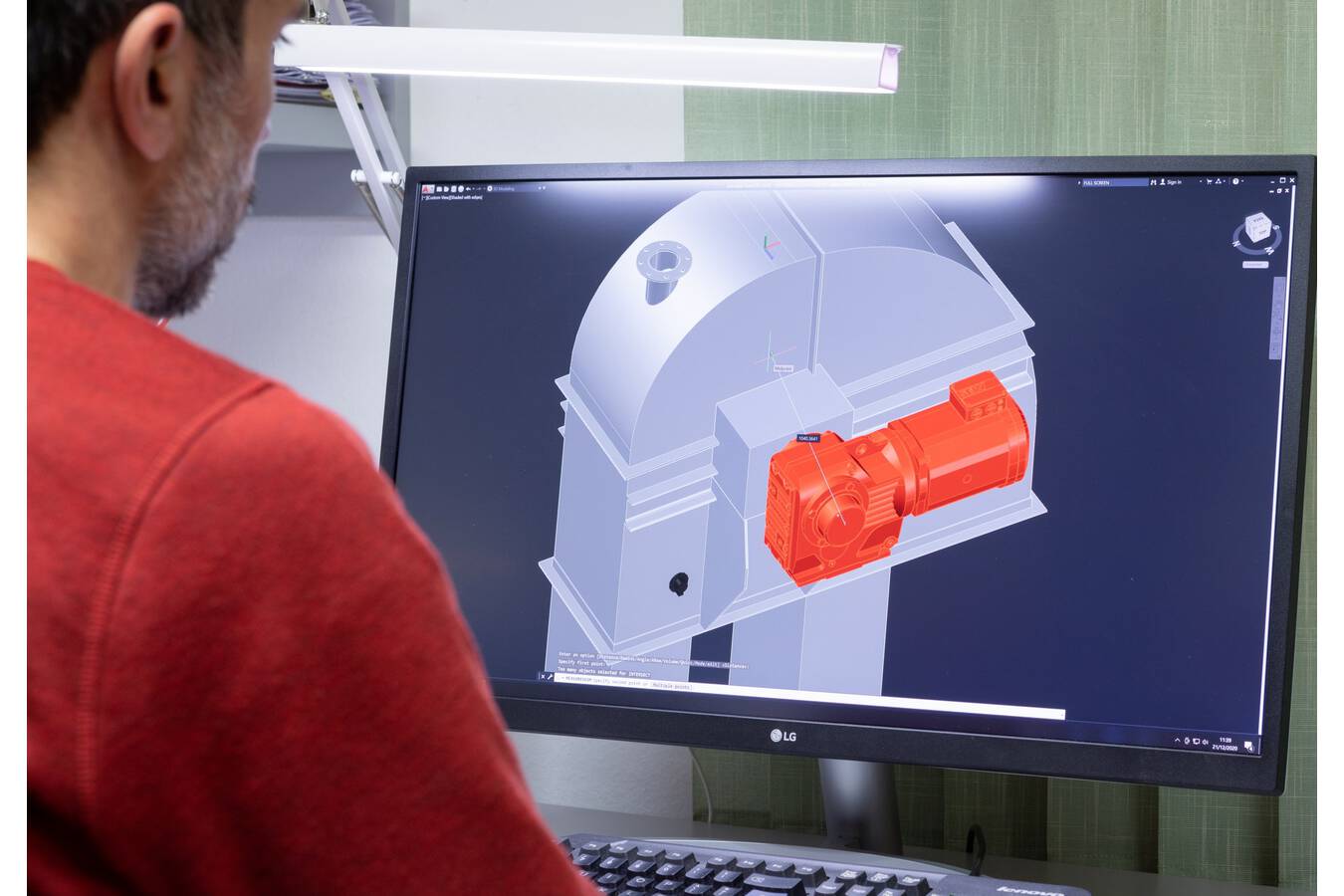

Laboratory tests and pilot trials: A prerequisite for precision. At Sinfimasa, every elevator project begins with rigorous testing. Laboratory analyses and full-scale pilot runs are carried out to simulate real conditions and detect potential issues early. Typical tests include:

- Sieve and granulometry studies

- Flow and repose angle testing

- Moisture and cohesion evaluation

- Wear and hardness analysis

The right bucket elevator for each product

Vertical transport poses unique challenges, and only a tailored design ensures consistent performance and product integrity. Critical design variables are:

- Bucket material and geometry

- Drive system and speed

- Discharge zone design

Options and choices

- Steel buckets for high strength and durability

- Plastic buckets (HDPE, nylon, polyurethane) for fragile or easily damaged materials

- Belt or chain selection based on material behavior:

- Abrasion-resistant belts for aggressive solids

- Oil- or grease-resistant belts for fatty or sticky materials

- Heat-resistant belts, or use of chains for high-temperature products

- Food-grade belts where hygienic handling is required

- Carbon steel for industrial applications

- Stainless steel (AISI 304/316) for corrosive or sanitary conditions

- Internal linings with anti-wear plastics or steel to prolong service life

Unmatched advantages

The strategic value of a customized designed bucket elevator based on actual product data and bulk solid behavior, delivers unmatched advantages, such as:

- Fewer stoppages

- Long equipment life

- Minimal product degradation

- Lower maintenance

- Safer, cleaner operation

Conclusion

At Sinfimasa, we believe precision begins with the product. By testing material behavior before design, we ensure that every bucket elevator we manufacture is tailored to elevate your product efficiently, safely, and with maximum reliability.