Coperion Recycling Innovation Center: State-Of-The-Art Test Lab

Construction of a new state-of-the-art test laboratory for plastics recycling applications. Forward-looking investment for more sustainability in plastics recycling. Coperion GmbH has initiated the construction of a state-of-the-art recycling test lab at its Niederbiegen/Weingarten, Germany, production facility.

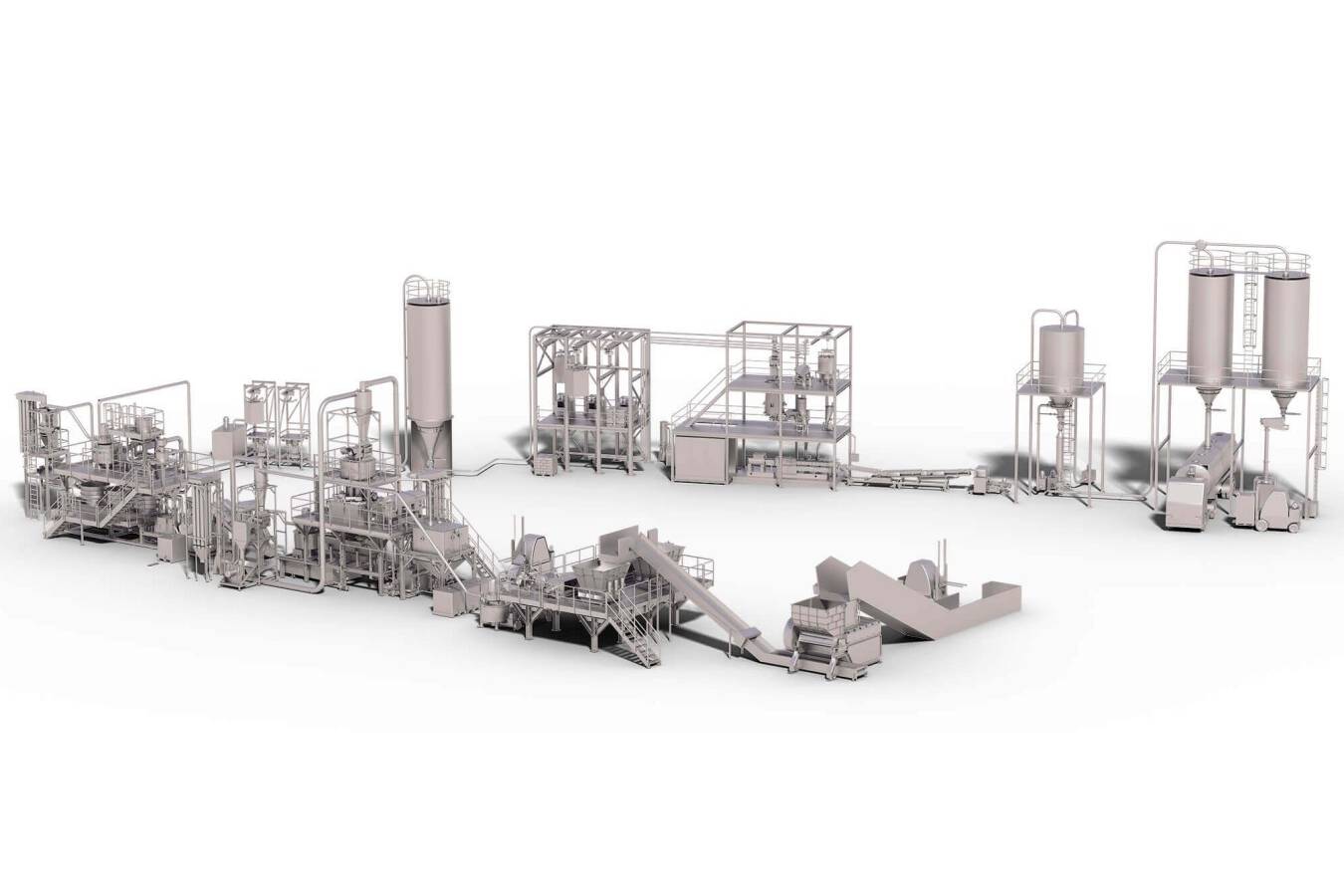

The new Coperion Recycling Innovation Center will be built in the immediate vicinity of Coperion’s existing Test Center for Bulk Solids Handling. Driven by rising demands worldwide for a circular plastics economy, a clear trend has taken shape over the last years toward more recycling. Coperion is meeting this trend, not only with its equipment and processes designed for recycling applications, but also with its new Recycling Innovation Center.

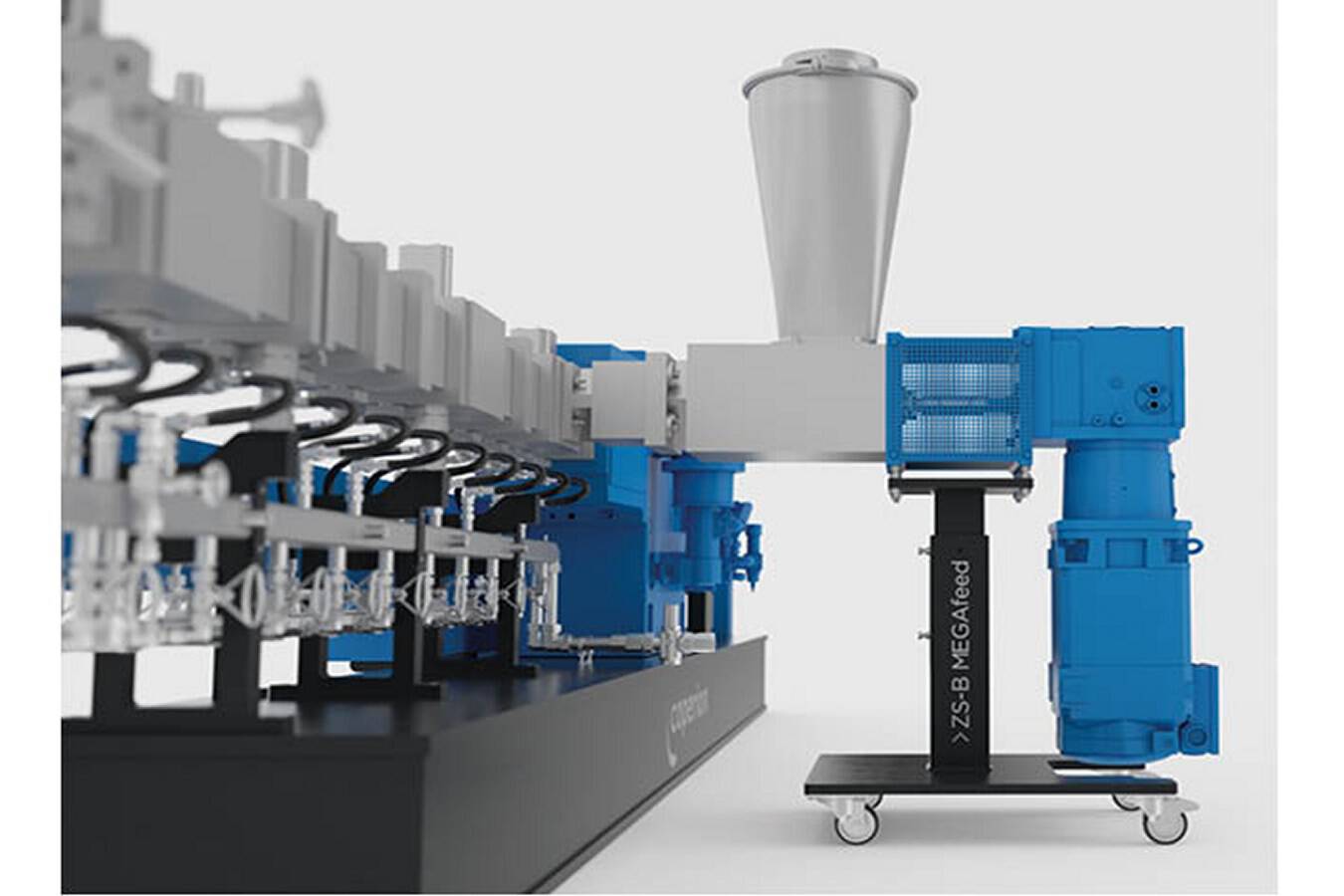

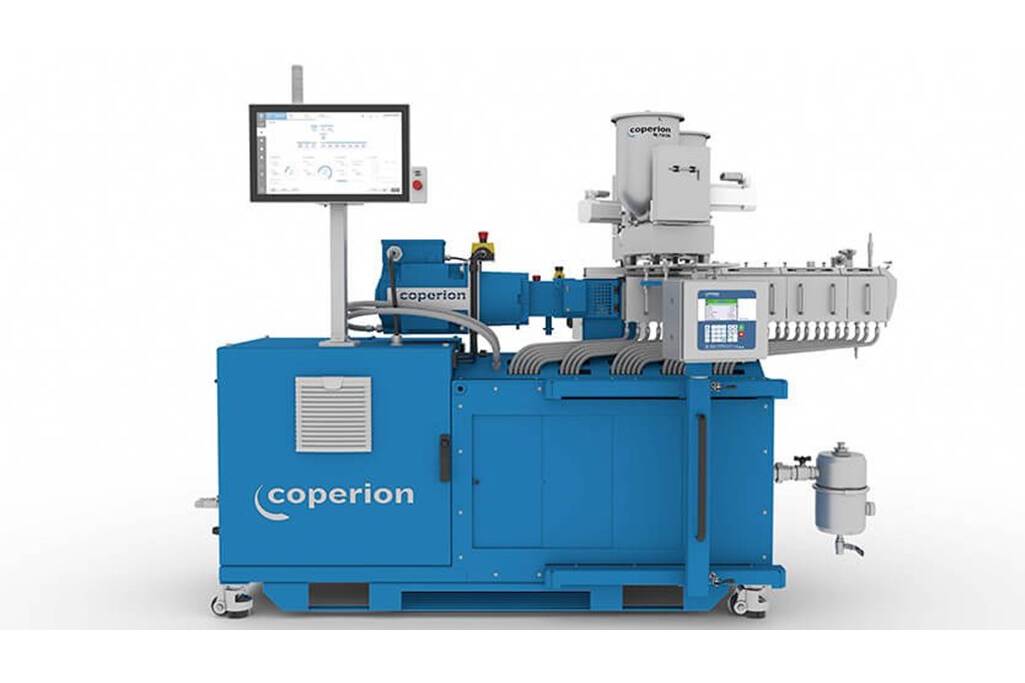

At the facility, customers will be able to develop and test new, sustainable products and recycling processes together with Coperion’s experts. All essential recycling process stages will be covered within the facility including materials conveying, feeding, extrusion, pelletizing, and materials postprocessing. In addition, Coperion will conduct its own research activities