Strategic collaboration

This strategic collaboration integrates Coperion’s expertise in continuous processing with HPB’s battery technology. HPB’s solid-state batteries offer significant improvements in safety, longevity, and environmental impact, with intellectual property protected in 96 countries. The technology provides up to 50% better environmental balance compared to conventional lithium-ion batteries, marking a key step toward sustainable energy storage.

Successful trials confirm production feasibility

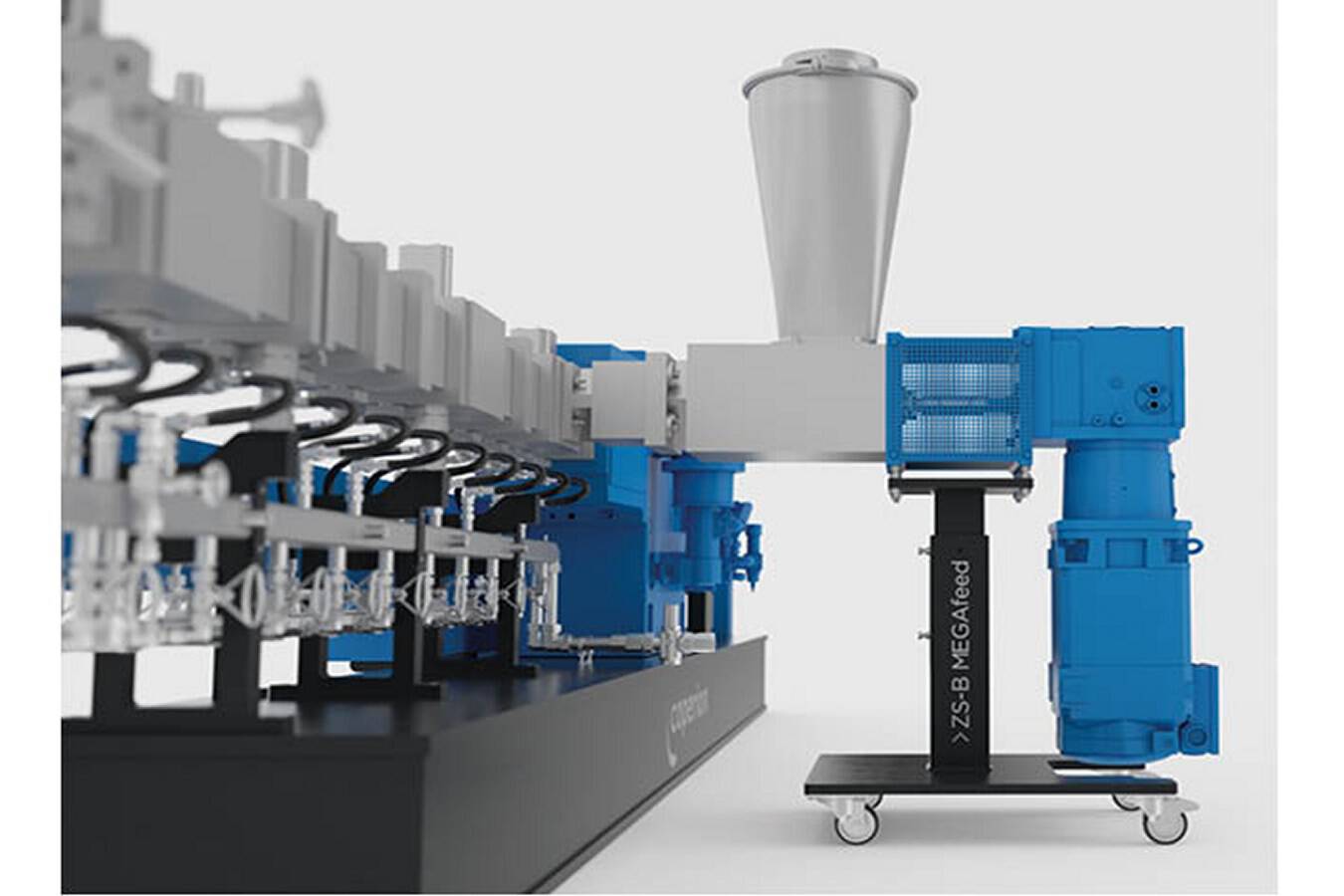

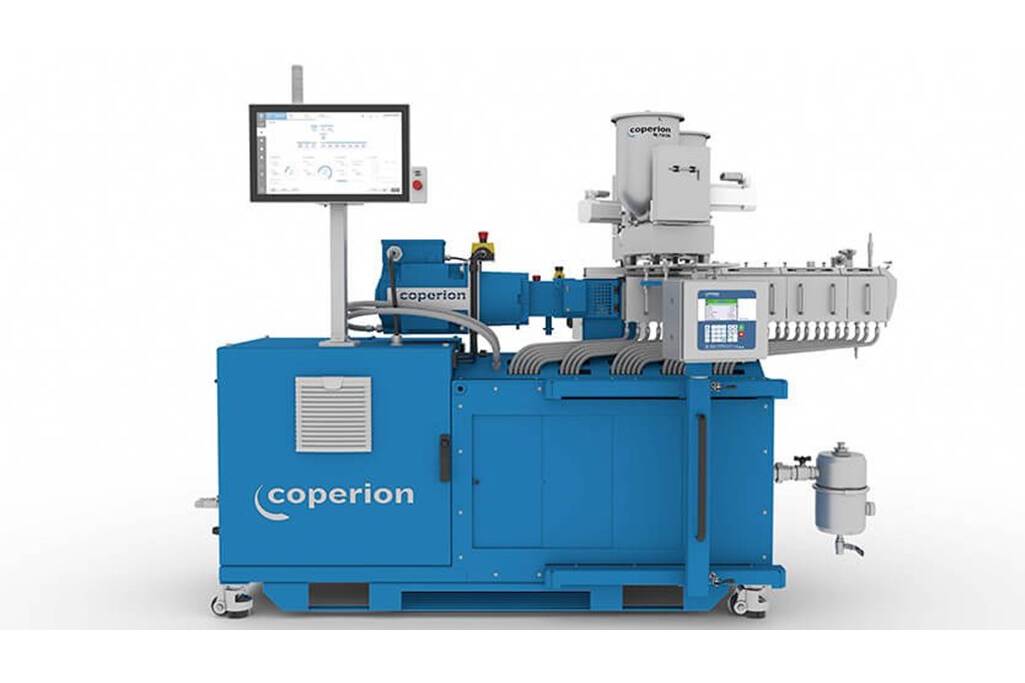

Earlier this year, HPB and Coperion conducted joint tests at Coperion’s facility in Stuttgart, Germany. Using Coperion’s continuous extrusion systems, the teams examined whether HPB’s slurry parameters could be effectively achieved. The first tests successfully demonstrated that the target viscosity could be met, which opened the door to further investigation and confirmed the potential for industrial-scale production.

Markus Stichnote, Head of Development at HPB, explained, “Our primary goal was to validate that our proprietary slurry can be produced reliably and consistently at industrial scale. The successful trials using Coperion’s state-of-the-art equipment have confirmed that scaling up our technology is both feasible and efficient.”

From lab to industrial production

Coperion brings extensive expertise in scaling innovative material processes from laboratory to industrial production. Massimo Bernert, Teamleader Sales Europe from Coperion, said, “We are delighted to support HPB in translating their innovative battery tech into scalable production. By applying our advanced continuous mixing solutions, we demonstrated that even novel battery formulations can be produced safely, efficiently, and at scale.”

Next steps in slurry production development

Following the successful achievement of target viscosity in the initial tests, the teams will consider scaling up trials in the next rounds, with the ultimate goal of achieving industrial-scale production in the future. Stakeholders are invited to connect with HPB and Coperion to explore partnership opportunities:

- battery manufacturing

- renewable energy

- clean technology sectors